Assessment of Problems Associated with Poor Project Management Performance

The purpose of this paper is to provide an explanation of the methodology and resources that Long International uses to arrive at its opinions on allocation of the responsibility for various problems, and the impact of those opinions on the parties’ entitlement to damages or extensions of the time of performance allowed under a contract.

1. INTRODUCTION

1.1 PURPOSE

Long International and other experts are often called upon to testify during mediations, arbitrations, and court cases on the consequences of poor Project Management performance that have occurred during the execution of construction projects. These impacts may have been caused by either party to a Contract, i.e., the owner or the contractor, or, sometimes, a subcontractor or supplier.

The purpose of this paper is to provide an explanation of the methodology and resources that Long International uses to arrive at its opinions on allocation of the responsibility for various problems, and the impact of those opinions on the parties’ entitlement to damages or extensions of the time of performance allowed under a Contract.

1.2 WHAT IS A CONSTRUCTION PROJECT?

For the purposes of this paper, we will define a “Construction Project” by drawing on the Project Management Institute’s (PMI’s) definition of a “Project” from the Guide to the Project Management Body of Knowledge (PMBOK® Guide),1 from PMI’s further discussion of the uniqueness of construction projects provided in the “Construction Extension to the PMBOK® Guide,”2 and from Long International’s experience.

PMI defines a “Project” as a “temporary endeavor undertaken to create a unique project or service.” PMI then provides examples such as “developing a new product or service,” “effecting a change in structure, staffing or style of an organization,” “constructing a building or facility,” and others.3

In the Construction Extension to the PMBOK® Guide, PMI expresses the uniqueness of construction projects:

- Construction projects produce a facility that will make or house the means to make a product or provide service facilities such as dams, highways and parks.

- They deal with geographical differences and natural events

- They may have a significant effect on the environment.

- They involve a team of hired specialists in design and construction disciplines.

- They involve many stakeholders, such as environmental and community groups.

- They require large amounts of materials and physical tools to move or modify those materials.4

Construction projects are also prime examples of projects that require progressive elaboration. According to PMI:

Progressive elaboration is a characteristic of projects that integrates the concepts of temporary and unique. Progressive elaboration means developing in steps, and continuing in increments.5 For example, the project scope will be broadly described early in the project, and made more explicit and detailed as the project team develops a better and more complete understanding of the objectives and deliverables. …

Progressive elaboration of a project’s specifications needs to be carefully coordinated with proper project scope definition, particularly if the project is performed under Contract. When properly defined, the scope of the project – the work to be done – should be controlled as the project and product characteristics are progressively elaborated. …6

PMI further provides an example of progressive elaboration by referring to the development of a chemical process plant:

Example 1: Development of a chemical process plant begins with process engineering to define the characteristics of the process. These characteristics are used to design the major processing units. This information becomes the basis for engineering design, which defines both the detail plant layout and the mechanical characteristics of the process units and ancillary facilities. All of these result in design drawings that are elaborated to produce fabrication and construction drawings. During construction, interpretations and adaptations are made as needed and subject to proper approval. This further elaboration of the characteristics is captured by as-built drawings, and final operating adjustments are made during testing and turnover.7

The discussion about progressive elaboration is important, especially for construction projects, because the elaboration steps are carried out over an extended period of time, often for years on large projects. One of the challenges that Project Management faces in this regard is to maintain the consistency of the project’s scope throughout project execution. This challenge continues through all the phases of the project life cycle.

The life cycle phases of a construction project, using an Engineering, Procurement, and Construction (EPC) Contract as an example, typically include:

- The Conceptual Phase, including the owner’s development of the project’s first goals, design concepts, initial design calculations, and order of magnitude cost estimates, identification of financing mechanisms, taking the pulse of the public and regulatory agencies on the concept, etc.

- The Preliminary Phase (sometimes called the basic design phase), including preliminary design calculations and preliminary plot plans and basic design drawings, development of permit packages and filing major permit applications, development of a contracting strategy, obtaining approval of major financing, ordering of long-lead-time equipment, and development of an EPC Contract and bid package.

- The Bid Phase (or Contracting Phase), including identification of qualified bidders, solicitation and analysis of bids, clarification of the bids, and negotiation and award the EPC Contract.

- The EPC (or Execution) phase, including all detailed engineering, procurement and construction activities, Project Management activities identified as the contractor’s responsibility, pre-commissioning and startup activities, and possibly commissioning and initial operations activities.

- The Commissioning and Initial Operation phase, if not included above.

- The Warranty period.

Construction projects may develop grass-roots facilities, or they may remodel, refurbish, or expand existing facilities. Routine maintenance operations may also be combined with construction projects.

1.3 WHAT IS PROJECT MANAGEMENT?

Again, we will rely on PMI to provide our starting point for a definition of Project Management.

Project Management is the application of knowledge, skills, tools, and techniques to project activities to meet project requirements. Project management is accomplished through the application and integration of the project management processes of: initiating, planning, executing, monitoring and controlling and closing. The project manager is the person responsible for accomplishing the project objectives. Managing a project includes:

- Identifying requirements

- Establishing clear and achievable objectives

- Balancing the competing demands for quality, scope, time and cost

- Adapting the specifications, plans, and approach to the different concerns and expectations of the various stakeholders.

…

It is important to note that many of the processes within Project Management are iterative in nature. This is in part due to the existence of and the necessity for progressive elaboration in a project throughout the project life cycle. That is, as a project management team learns more about a project, the team can then manage to a greater level of detail.8

We also recognize that there are other definitions, some of which refer to Project Management as a “set of principles,” but other definitions generally use somewhat different phraseology to say the same thing.

2. THE IMPORTANCE OF SOUND PROJECT MANAGEMENT PRACTICES

The application of sound Project Management practices provides construction project stakeholders with the means to meet their objectives. These include ensuring that the project, i.e., the building or facility is:

- Constructed to meet its intended purpose, and only its intended purpose;

- Constructed to meet the level of quality that was intended;

- Completed when it is supposed to be done;

- Completed for its intended cost; and

- Completed safely and while protecting the environment.

The lack of sound Project Management by owners or contractors on projects leads to construction delays and extra costs for both parties. In addition to the problems that occur during construction, poor Project Management can also result in a completed facility that fails to meet the specified quality and suitability of materials, fails to produce the intended products, or cannot be operated for its intended life. This usually results in claims from contractors and counterclaims from owners, or vice-versa depending on who decides to sue whom.

In Long International’s experience, reasons for failure determined during project management assessment that are often cited during disputes include

- The failure of the Project Management team to adequately plan the work, or, when a plan is developed, to properly execute that plan.

- The failure to provide adequate human resources, staff or direct labor, to the project.

- The failure to develop adequate project schedules, or to maintain those schedules throughout project execution.

- The failure to control costs and changes throughout the execution of the project.

All of the above can be attributed at some level to inadequately trained or under-resourced Project Management teams.

In today’s business environment, the application of sound Project Management principles on a project is not only the means to the ends listed above, but, during disputes, can also provide a level of defense against alleged management deficiencies that resulted in delays and additional costs. Demonstrating that you used sound Project Management practices, and that the other party did not, can help your side win disputes.

3. PROJECT MANAGEMENT REQUIREMENTS STATED IN THE CONTRACT

Project management requirements are usually prescribed in major engineering and construction Contracts, particularly in large EPC and Lump Sum Turn Key (LSTK) Contracts. These Contracts typically state each party’s Project Management duties. These duties include requirements for development, review, approval, and implementation of:

- General Project Execution Plans and additional detailed supporting plans for each management area

- A statement of the Scope of Work for the Project

- Scheduling requirements naming the types and frequencies that various schedules must be produced and how they are to be updated

- Change Control

- Cost control and reporting

- Quality management

- Staffing and hourly labor manpower levels

- Performance reporting

- Insurance and bonding

- Subcontract management

- Management of materials and permanent equipment

- Job-site safety

- Protection of the environment

- Claims procedures

In the course of a dispute, a contractor’s failure to perform its duties under the above requirements may result in loss of entitlement to any time extension or damages attributable to those failures. Similarly, an owner’s failure to perform its duties may result in its inability to defend against delay and additional cost claims attributable to those areas.

3.1 EXAMPLES OF PROJECT MANAGEMENT REQUIREMENTS FROM AN EPC CONTRACT

As an example of the typical duties stated above, an EPC Contract executed between an owner company and a contractor included the following requirements under “Contractor Responsibilities and Representations:”

3.2.3 Required Skills and Capacity to Perform

It (the Contractor) has the required skills and capacity to perform, and shall perform, the Work in a professional manner utilizing sound engineering, procurement and construction principles, current management information systems and electronic communication systems, project management and supervisory procedures in accordance with the Agreement, Engineering Record, and accepted practices in the industry. Its key personnel are as identified in Exhibit 8. (Emphasis added.)

Note that even in a large EPC Contract that one might consider to be all-inclusive in its internal statements of scope and technical specifications, the requirement to use “accepted practices in the industry” still exists. This statement, unless further defined to the satisfaction of the parties, can result in misunderstandings that lead to disputes.

Another EPC Contract involving the addition of power cogeneration to an existing plant identified the following Project Management related documents that the contractor had to produce during the course of the work. These may be called “deliverables” or “submittals.”

- Plans and Procedures

- Project Execution Plan

- Staffing Plan

- Change Control Procedures

- Communications Procedures

- Procurement Plan

- Quality Assurance Program

- Transportation Plan

- Construction Plan

- Tie-in Plan

- Shutdown Plan

- DCS Training Plans

- Performance Testing Plan

- Turnover Plan

- Startup and Pre-commissioning Plan

- Surplus Materials Plan

- Safety Procedures Manual

- Schedules

- Project Master Schedule

- Construction Schedule

- Steam Tie-in Schedule

- Power Tie-in Schedule

- Equipment Movement Schedule

- Mechanical Acceptance Schedule

- Payment Schedules

- Insurance Certificates

- Progress Reports

- Proposed Products List

- Samples

- Manufacturer’s Instructions

- Manufacturer’s Field Reports

The Contract mentioned above also noted a specific and rather extensive definition of the owner’s Project Management role in the review and approval of these submittals, as well as for other Contract requirements. The owner was required to review or approve documentation in the twenty three (23) areas shown below:9

| 3.2.8 | Quality Assurance Programs |

| 3.2.11 | Removal of Key Personnel |

| 3.2.17 | Disposition of Surplus Items |

| 3.2.20 | Site Cleanup Program |

| 3.7 | Subcontractors and suppliers used in connection with the WORK. |

| 4.3 | Gas Turbine Generator Availability Study |

| 4.6 | Master Schedule |

| 4.10 | Acceleration Plans |

| 5.2.4 | Mechanical Acceptance Certificate |

| 5.3 | Commissioning Methods and procedures |

| 5.4 | Commercial Acceptance Certificate |

| 5.6 | Final Acceptance Certificate |

| 7.1.1 | Payment Milestones |

| 7.1.2 | Material and Equipment Requisitions |

| 7.5 | Invoice Payment |

| 9.2 | Subcontractor and vendor warranties and guarantees |

| 10.1 | Changes in the work |

| 14.1 | Contractor-Furnished Insurance Certificates |

| 17.1 | Assignments (e.g., subcontracting part of the work) |

| 17.2.4 | Contractor negotiations with governmental agencies |

| 17.3.5 | The use of photographs of any Company facility |

| 17.7 | Public Relations Communications |

| 17.9 | Accounting Records and Right to Audit |

One of the contractor’s key arguments in a dispute related to the above Contract was that the owner had overstepped the bounds of what the contractor argued was the owner’s “limited” Project Management role on the project by interfering with the contractor’s means and methods of execution. Long International was able to defeat this argument by demonstrating that the owner performed in accordance with the clear language of the Contract.

3.2 CLARITY AND SUPPORT OF CONTRACT REQUIREMENTS

It is imperative that the Contract project management requirements be understood by both parties. Because the owners of major construction projects are typically the authors of the Contracts, contractors often attack the validity of Contract requirements based on alleged unclear language and a resulting different interpretation of the requirements than is being expressed by the owner. It is an advantage to the owner, therefore, to use clear language that can also be supported by generally accepted standards of Project Management performance.

PMI, the Construction Industry Institute, and other respected institutions have created a large body of work that can be referenced by the authors of Contracts to support the Project Management requirements shown in them.

4. PROJECT MANAGEMENT PRACTICE GENERALLY ACCEPTED IN THE INDUSTRY

No Contract can address every eventuality that will occur during the execution of a project. When disagreements occur, one party or the other will often claim that what it was required to do or how the other party behaved was not in accordance with “normal industry practice” or “accepted practices in the industry” as discussed above. When this occurs, there are resources available to aid in the determination of what “normal industry practice” is.

When assessing a party’s Project Management performance that is not explicitly defined by the Contract, Long International compares that performance with practices published by well known and respected institutions such as PMI, CII and others, as well as the experience of its own personnel gained from many years of successfully executing major projects.

4.1 PMI’S GUIDE TO THE PROJECT MANAGEMENT BODY OF KNOWLEDGE (PMBOK® GUIDE) AND THE CONSTRUCTION EXTENSION

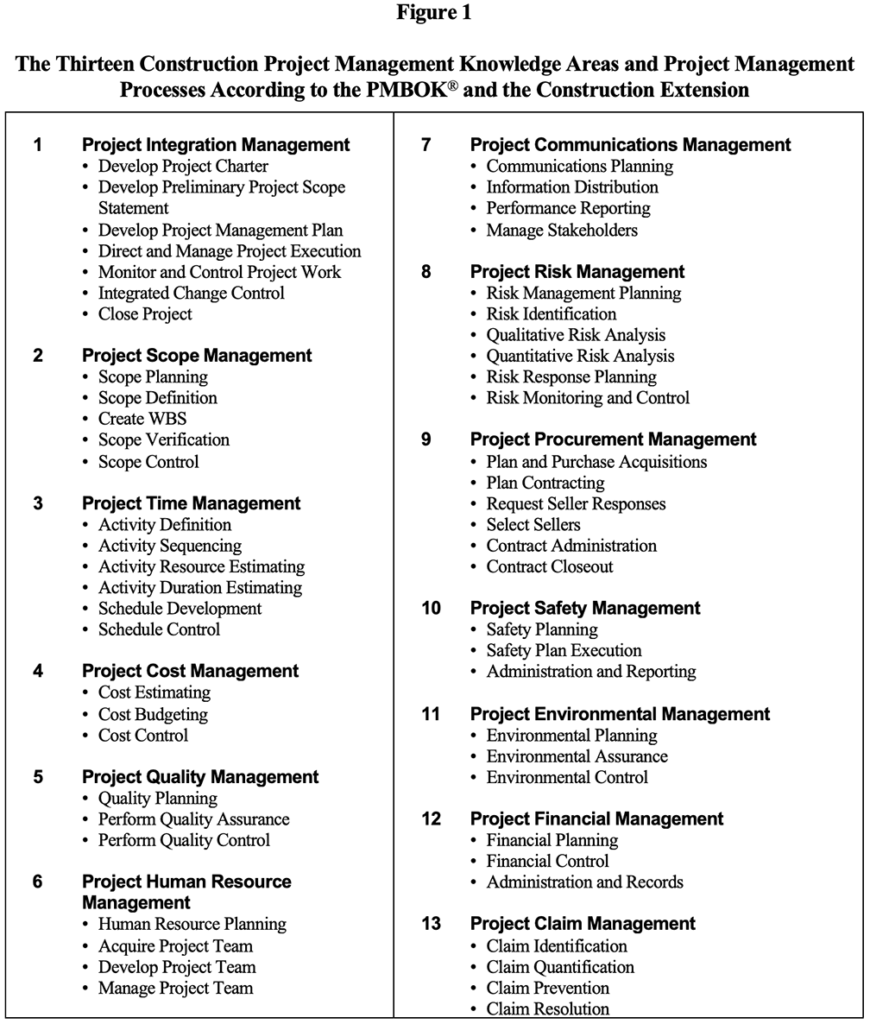

PMBOK® divides the Project Management functions into nine knowledge areas,10 and the Construction Extension adds four more areas particular to the construction industry.11 Combined, these are:

- Project Integration Management

- Project Scope Management

- Project Time Management

- Project Cost Management

- Project Quality Management

- Project Human Resource Management

- Project Communications Management

- Project Risk Management

- Project Procurement Management

- Project Safety Management

- Project Environmental Management

- Project Financial Management

- Project Claim Management

A breakdown of the Project Management processes associated with each of the above knowledge areas is shown in Figure 1 at the end of this article. Integration management, for instance is made up of seven processes, including:

- Develop Project Charter

- Develop Preliminary Project Scope Statement

- Develop Project Management Plan

- Direct and Manage Project Execution

- Monitor and Control Project Work

- Integrated Change Control

- Close Project12

While application of all of the Project Management processes associated with these knowledge areas is needed for the success of a project, some may not be explicitly called out in a given Contract. Financial Management, for instance, may be left for the individual parties to handle apart from the contract. The owner would have to acquire project financing, make sure that funds could be distributed as needed, and handle accounting for capitalization purposes, but the contractor would have no involvement in those processes. Conversely, the contractor would have to acquire his own financing for his needs, and control those funds. The fact that requirements for financial management are not addressed in the Contract does not mean that Financial Management is not needed. Quite the opposite, a failure in Financial Management can mean the disastrous failure of the project.

In Long International’s experience, some Contracts, lump-sum in particular, tend to lack detail in the areas of Risk Management, Communications Management, Procurement Management, and Integrated Change Control processes. This leaves a lot of room for disagreements in these areas; therefore an outside standard must be relied upon to determine which party’s point of view is right.

The PMBOK® and the Construction Extension provide an excellent structure for general Project Management requirements. During the resolution of disputes, Long International has been successful in attributing responsibility for poor Project Management or project failures, and in determining who is entitled to recovery of additional costs and time as a result of a party’s failure to implement the Project Management knowledge areas and processes.

When the parties have implemented the basic Project Management processes discussed above and there are still disagreements, a more detailed analysis of the processes and how they were executed is needed.

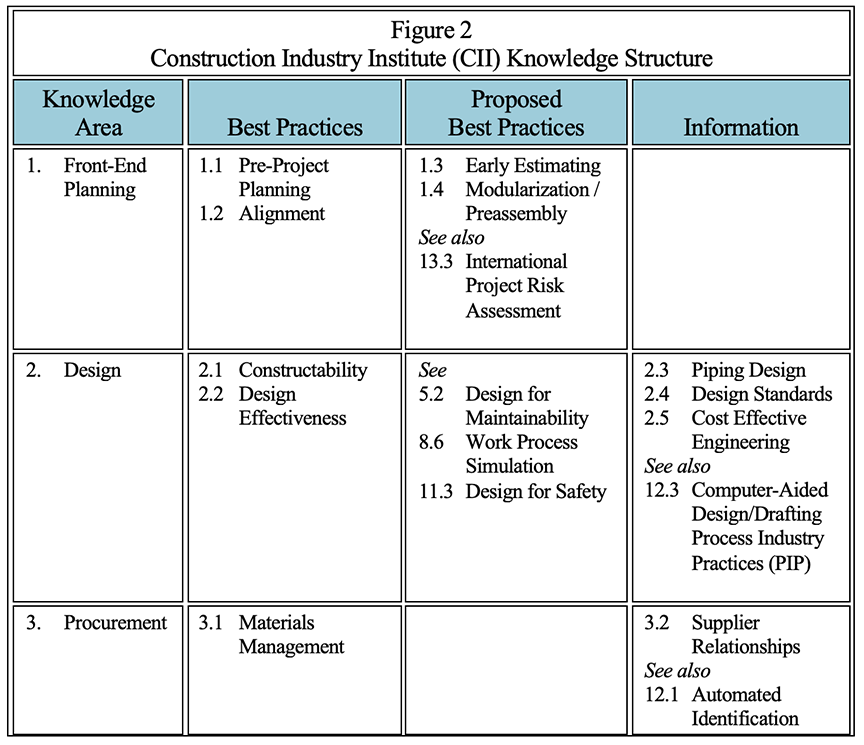

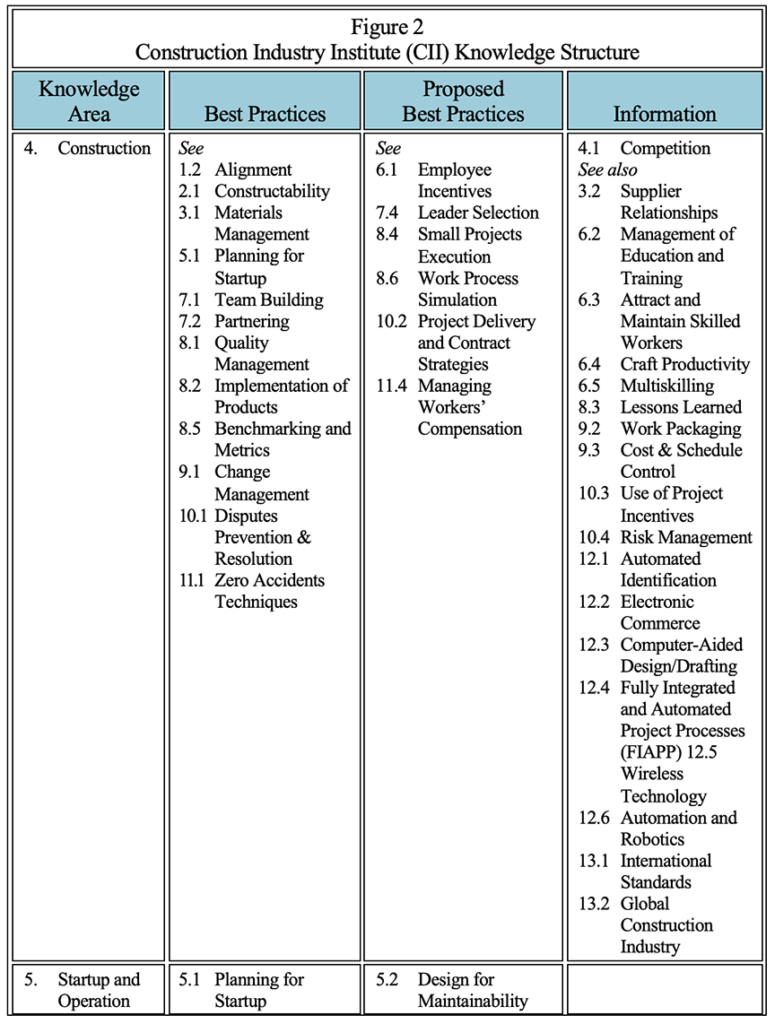

4.2 CII’S KNOWLEDGE STRUCTURE

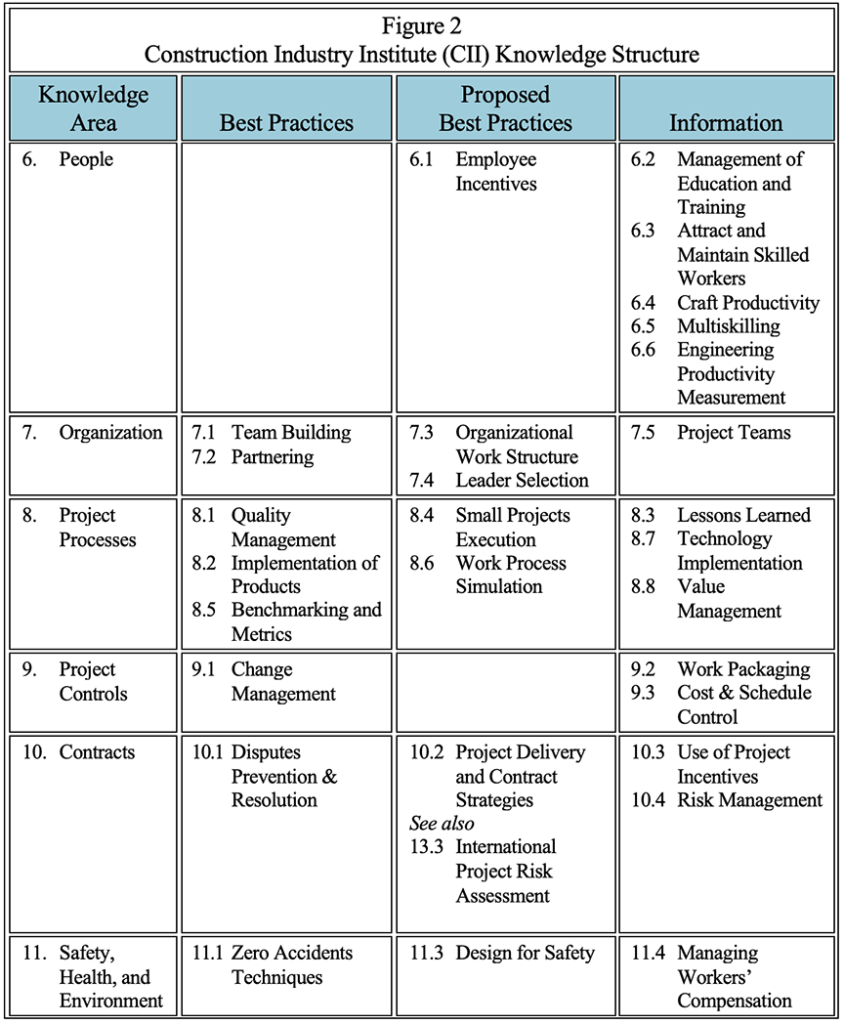

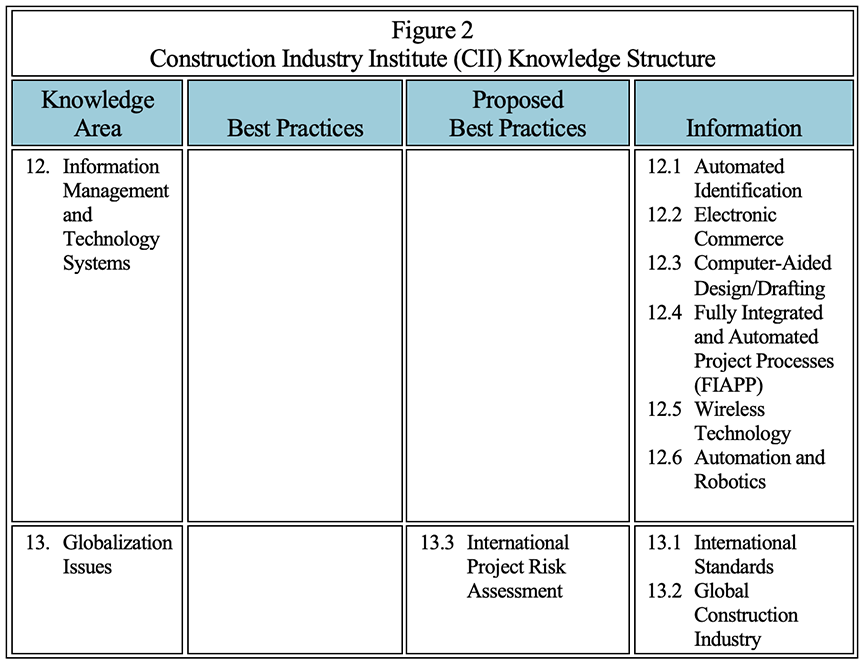

One part of this more detailed analysis is comparison with the best practices available and recognized by the construction industry. One such source of best practices is the Construction Industry Institute (CII). CII presently is an organization of approximately 90 companies and government agencies that are owners or contractors on the largest and most complex construction projects executed in the U.S. and internationally. Their scope covers oil and chemical companies, aerospace, food, timber, pharmaceuticals, power, and others. CII sponsors the basic research for and the development of “Best Practices” and other helpful supporting information, and has organized this work into a “Knowledge Structure.”

CII has organized its Knowledge Structure as a matrix that presents detailed CII publications by topic. These are individual instructive publications, i.e., “how-to-do-it” books, called “Best Practices,” “Proposed Best Practices,” and “Information.” The Knowledge Structure is divided into thirteen major “Knowledge Areas,” all of which are focused on construction projects. The CII Knowledge Structure and publications are available when needed to both expand the scope of our Project Management analyses and to lend more detailed support to our findings.

CII’s Thirteen Knowledge Areas are:

- Front-End Planning

- Design

- Procurement

- Construction

- Startup and Operation

- People

- Organization

- Project Processes

- Project Controls

- Contracts

- Safety, Health, and Environment

- Information Management and Technology Systems

- Globalization Issues

CII’s Knowledge Structure showing the individual Best Practices, Proposed Best Practices, and Information publications is shown in Figure 2 at the end of this article.

Long International has successfully used CII best practices as support for its expert opinions related to construction scheduling, Change Order Management, assessment of the impact of Change Orders on the cumulative impact of delay, and assessment of engineering and construction labor productivity. Among the publications that Long International has successfully relied upon are:

- Publication 6-10: The Impacts of Changes on Construction Cost and Schedule

- EM113-22: Scope Control and Change Management

- Research Summary 158-1: Quantifying the Cumulative Impact of Change Orders for Electrical and Mechanical Contractors

- Source Document 108: Quantitative Impacts of Project Change

- Special Publication 43-1: Project Change Management

4.3 OTHER RESOURCES

Beyond those discussed above, there are other organizations that publish “best practices” and other resources that can be used to compare to the actual Project Management practices an owner or contractor may have used on a project. Other organizations, for example, include:

- The Association for the Advancement of Cost Engineering (AACE) International, which provides “Professional Practice Guides” such as “Estimating Lost Labor Productivity in Construction Claims,” other publications on cost management, and a certification program for “Cost Consultants,” “Cost Engineers,” and other specialties.

- The American Institute of Architects (AIA), which provides Contract forms used widely throughout the building construction industry as well as publications on the management of design-build services and others.

- The Center for Business Practices (CPB), which sponsors benchmarking forums and publishes resource books.13

- The Construction Management Association of America (CMAA), which offers various Construction Project Management related publications and a construction manager certification program.14

- The Project Management Institute’s College of Scheduling has organized a Scheduling Excellence Initiative (SEI). SEI is a two-year program attempting the first global standardization and improvement of scheduling services and products since the inception of CPM nearly 50 years ago.

5. MEASURING CONFORMANCE TO THE PROJECT MANAGEMENT REQUIREMENTS OF THE CONTRACT

When Construction Project Management problems are part of a dispute, we have to determine which party is responsible for each of those problems. As discussed above, Project Management requirements are normally laid out in the Contract documents. The first step in Long International’s analysis is to identify those requirements and create a compendium of them against which to compare alleged failures.

5.1 DELIVERABLES

Using a contractor’s duty to provide certain deliverables, for example, we would create a document that identifies the detailed requirements for each deliverable. The requirements may identify both the necessary content of the deliverable and when it needs to be provided. For example:

5.1.1 Project Execution Plan

The Contract may require that a Project Execution Plan be provided along with the contractor’s bid and then be updated periodically throughout the Contract period. This plan typically contains statements of the project’s goals and objectives, the Project Management approach, scope, budgets and project control methods, performance measurement, preliminary schedule and major milestones, staffing and other resources needed, risk management, and supporting plans that need to be developed.

Once the requirements are identified, the actual plan that the contractor produced can be easily compared with the Contract requirements to determine if they were met. This requires not only that the original plan be reviewed, but also that subsequent updates were created according to the timing shown in the Contract and when significant events demand that the plan be changed to meet new or changed requirements. A poorly done or untimely plan is an indication of deficient Project Management.

5.1.2 Project Schedules

EPC Contracts typically require Project Schedules be developed using the CPM method, and often that particular computer software such as Primavera Project Planner (P3) or MS Project be used. An excerpt from the schedule requirements of an actual Contract states:

4.6 Master Schedule. Within 30 days following the Contractor’s receipt of the Notice to Proceed and in accordance with the provisions of this Agreement Contractor shall submit to Company, for Approval, a detailed schedule showing all Work Contractor proposes to perform during the first 90 days following said notice; on or before the end of said 90 day period Contractor shall submit to Company, for approval, a detailed schedule (including critical path networks covering each task of the Work including delivery of all equipment and materials), showing the tasks and related sequence of tasks Contractor proposes to perform the Work and achieve the requirements of this Agreement, including the schedule requirement of this article. Following Approval by Company this schedule shall be the Master Schedule. Thereafter, Contractor may present to the Company proposed amendments to the Master Schedule in a form satisfactory to Company and shall furnish in support of such proposed amendments such additional details and information relating to the Master Schedule or the Work as Company may request. Any proposed amendment shall be effective only upon Approval. Following Approval the amendment shall be included as an appendix to Exhibit 3. The Contractor shall implement the Master Schedule to minimize or eliminate the impact of any delay and to facilitate the orderly, efficient progression of the Work.

In addition to the requirements shown above, the specifications of this Contract also required that the schedule be developed in accordance with a particular work breakdown structure, that schedules for mechanical acceptance and commissioning be developed at particular times, that updates be presented to the owner monthly, and that the updates be presented showing multiple levels of detail (e.g., Level 1 – Summary, Level 4 – Detailed).

Similar to the discussion on the Project Execution Plan above, the Project Schedule can also be evaluated to determine its compliance with Contract requirements. An analysis that shows that the schedule and its updates were not done when required, did not include all the elements of the work, and had defective logic or other errors would show that this contractor failed to properly schedule the project. This would demonstrate a significant failure in Time Management.

The Contract quoted above also contained a provision that required the contractor to actually adhere to the schedule, and, if problems occurred, to add manpower or take other measures to get back on schedule. Even if the contractor’s scheduler had developed the schedule correctly, the field staff’s failure to use it is a strong indication of deficient Project Management.

5.1.3 Progress Reports

The specifications of the Contract discussed above required that the contractor provide a monthly narrative progress report that presented problems areas, anticipated delays and their anticipated impacts on the schedule, recommended corrective actions and their intended impacts, and the effects of changes on the schedules of other subcontractors.

Again, the progress reports can be reviewed to determine if they contain the type of information required, if they were published when required, and if they were accurate. The accuracy of progress reports can be determined by comparing them with project correspondence, meeting minutes, memoranda, and supervisors’ log books that were prepared contemporaneous with the work. Any disconnect between these documents is an indication of poor communication management on the job, or sometimes, unwillingness to admit the truth on the part of those writing the reports.

A failure to properly develop the above deliverables can be used to show that a contractor failed to properly plan, schedule or control the Project from the very beginning. This failure can lead to the loss of his entitlement to a schedule extension or damages.

5.2 CONTEMPORANEOUS DOCUMENTS

In addition to the above, contemporaneous project documentation can be analyzed to determine whether the parties actually executed the Project in accordance with the Contract requirements. This documentation includes:

- Project Plan updates

- Schedule updates

- Periodic reports

- Correspondence

- Requests for Information

- Change orders (approved or not)

- Superintendents’ log books

- Other contemporaneous documents such as photographs, telephone call records, etc.

On Projects that Long International has analyzed, these documents have shown many Project Management deficiencies:

- Where Project plans have shown the staff and hourly labor requirements for the Project, periodic reports and correspondence have shown that the contractor did not provide sufficient manpower to meet the planned levels.

- Progress reports have shown that the contractor did not place orders for material in accordance with the schedule, with the schedule in turn showing that this failure impacted the critical path.

- Change Orders have not been developed in accordance with the detail and timeliness required by the Contract, and have indicated that the contractor agreed that there would be no affect on the contractual completion date as a result of performing the changed work.

- Superintendents’ log books have pointed out the contractor’s own deficiencies that led to delays or additional costs.

- Correspondence has shown misunderstandings among subcontractors that led to conflicts on the job-site that negatively impacted worker productivity.

- Requests for Information have shown that the owner did not properly respond in a timely manner to the contractor’s request for clarification of potential piping and structural steel interferences in the design drawings, leading to delay in the performance of the contractor’s work until the design problems were corrected.

6. MEASURING CONFORMANCE TO GENERALLY ACCEPTED PROJECT MANAGEMENT PRACTICES

In the event that an issue is raised that is outside of the specific language of the Contract, the same documents listed above (Project Plans, Schedules, etc.) can be analyzed to compare the parties’ performance to the generally accepted Project Management practices discussed above. For example:

6.1 MATERIAL DELAYS

If the Contract did not require a specific type of Procurement Plan or Status Report from which to evaluate the contractor’s performance, did the contractor generate its own Procurement Plan, Schedule, etc., in accordance with a standard such as PMI’s Project Procurement Management standard? Provisions of this standard include development of a plan that shows the scope of the procurement effort, the required resources (e.g., people), market conditions, constraints on availability of funds, and market assumptions. Procurement activities also have to be shown on the Project Schedule to be properly integrated with the rest of the work.

A failure on the contractor’s part to properly plan its procurement work, even if a plan was not required by the Contract as a deliverable, would be an indication of deficient procurement management. Any resulting delays and extra costs would be the contractor’s responsibility.

6.2 CHANGE REQUESTS AND CHANGE ORDERS

If the Contract did not specify a particular format for development of Change Orders, did the contractor provide an adequate change tracking system, identify personnel authorized to approve the contractor’s Change Requests, identify the impact of the change on the Project Schedule, etc., in accordance with PMI’s Integrated Change Control standard?15

A failure on the contractor’s part to develop and control Change Orders in accordance with the steps noted above would be an indication of deficient Change Order Management. Typically, this failure results in disputes between the owner and contractor on whether or not the owner should approve a change request, and on the ultimate cost of the change. If the contractor was deficient in its Change Order Management, this deficiency can result in the contractor’s inability to recover costs and time impacts associated with the change.

7. ALLOCATION OF RESPONSIBILITY FOR POOR PROJECT MANAGEMENT TO DELAY AND DAMAGES CALCULATIONS

Various Project Management failures and how to determine which party was responsibility for them have been discussed above. The next challenge is to show how the delay and cost impacts of these problems can be allocated to the parties and quantified through project management assessment.

7.1 DELAY

Project management failures can impact scheduled project activities. A contractor’s failure in Procurement Management for instance, may lead to late award of subcontracts. Consider the following as-planned Project Schedule excerpt and the situation described below:

| Activity ID | Title | Early Start | Early Finish |

| 00000060 | CIVIL SUBCONTRACT – ISSUE REQUISITION | 4/2/96 | 4/23/96 |

| 00000061 | CIVIL SUBCONTRACT- OWNER APPROVE REQUISITION | 4/24/96 | 5/1/96 |

| 00000065 | CIVIL SUBCONTRACT – BIDDING & AWARD | 5/2/96 | 5/23/96 |

| 00000070 | CIVIL SUBCONTRACT – MOBILIZATION | 5/24/96 | 4/28/96 |

- In executing its work, the contractor developed a civil subcontract requisition, or bid package, using the wrong specifications for earthwork and road construction. In this case, the earthwork specification had included an incorrect statement of the scope of the road work.

- The owner, toward the end of his allotted review period, discovered the error and sent the requisition back to the contractor to be corrected.

- The contractor did not have any float in his schedule for rework of his documents, so the bidding of the civil subcontract was delayed.

If a schedule delay analysis then showed that this activity was on the critical path of the project and there was no concurrent delay, the responsibility for the delay would lie with the contractor. The actual number of days of delay attributable to the contractor’s failure to prepare a proper bid package would then be evident.

Another example shows the impact of a contractor’s failure to properly execute his testing and turnover plan.

| Activity ID | Title | Early Start | Early Finish |

| E01240120 | SOLID REACTOR SE-C-05. – TESTS & PRECOMMISSION. | 8/31/97 | 9/14/97 |

| E01240200 | SOLID REACTOR SE-C-05 – FUNCTIONAL CHECKOUT | 10/8/97 | 10/9/97 |

| E01240510 | SYSTEM PACKAGE AVAILABLE TO OWNER | 7/19/97 | 7/19/97 |

| E01240520 | OWNER PRE WALK-DOWN (START-UP TEAM) | 7/30/97 | 7/31/97 |

| E01240530 | JOINT WALKDOWN (CONT/OWNER) INSP/PUNCH SYSTEM | 9/15/97 | 9/18/97 |

| E01240540 | CONTRACTOR COMPLETE PUNCH LIST ITEMS | 9/19/97 | 9/28/97 |

| E01240550 | CONTRACTOR CHECK SYSTEM – QC DOCUMENTATION | 9/29/97 | 10/2/97 |

| E01240560 | SUBMIT QC DOCS TO OWNER START UP TEAM | 10/3/97 | 10/3/97 |

| E01240570 | FINAL JOINT WALK-DOWN / AGREE EXCEPTIONS | 10/4/97 | 10/5/97 |

| E01240580 | SYSTEM ACCEPTANCE BY OWNER | 10/6/97 | 10/6/97 |

| E01240590 | OWNER APPROVES PACKAGE | 10/7/97 | 10/7/97 |

| E01240625 | SOLID REACTOR SE-C-05. – TURNOVER | 10/7/97 |

In this case, the contractor developed and submitted a testing, pre-commissioning, and turnover plan to the owner that was approved prior to the start of the actual field work. Plan in hand, the owner showed up on-time for the first “joint walk-down” of the reactor on September 15th and asked for the design documents that were supposed to be provided at the walk-down.

Unfortunately, the contractor failed to provide the updated process and instrumentation diagrams and other design documents that were necessary to guide the inspection and punch-listing of the work. The drawings had not been completed. Two weeks later, the contractor produced the drawings and the joint walk-down commenced. This resulted in a two-week delay in the turnover of the facility to the owner.

Again, if a schedule delay analysis then showed that this activity was on the critical path of the project and there was no concurrent delay, the responsibility for the delay would lie with the contractor.

7.2 COSTS AND THE ALLOCATION OF DAMAGES

Regardless of who is the initiator, a claim must contain three essential elements before any damages can be recovered:

- Entitlement. What actions and/or inactions by the other party or parties to the Contract resulted in compensable liabilities?

- Cause and effect. Do the entitlements for the problems encountered bear a direct relationship to the financial damages that were incurred?

- Damage computation. What methodology or methodologies will be used for presenting and pricing the compensable (recoverable) damages?

There are numerous entitlements that are recognized by the U.S. federal courts, state courts, and arbitration panels leading to the recovery of damages related to a construction claim. These entitlements include:

- Acceleration,

- Acts of God/Weather,

- Cardinal change (breach of contract),

- Constructive change,

- Defective and deficient contract documents,

- Delays,

- Differing site conditions,

- Directed change,

- Disruption,

- Implied warranty,

- Impossibility of performance,

- Mal-administration,

- Owner-furnished items,

- Strikes,

- Superior knowledge,

- Suspension,

- Termination,

- Unjust enrichment, and

- Variations in quantities.

7.2.1 The Cause-Effect Relationship

Cause and effect relationships linking the entitlements to the damages are most often found in the project’s contemporaneous documentation, i.e., updates of the project plans and schedules, periodic reports, correspondence, Change Orders, Requests for Information, meeting minutes, superintendent’s logs, etc., as discussed above.

The ability to quantify damages, however, depends on the availability and analysis of detailed and verifiable man-hour and cost data. Having demonstrated the nature of the loss and the connection between the loss and the other party’s actions and/or inactions, the success of the claim will often hinge on how well the claimant can calculate and prove its damages. Conversely, the parties to a Contract should understand the principles of proof of damages to properly and fairly evaluate a claim, grant the cost and time request if they are justified, or reject the claim if convincing and supportable evidence is not presented.

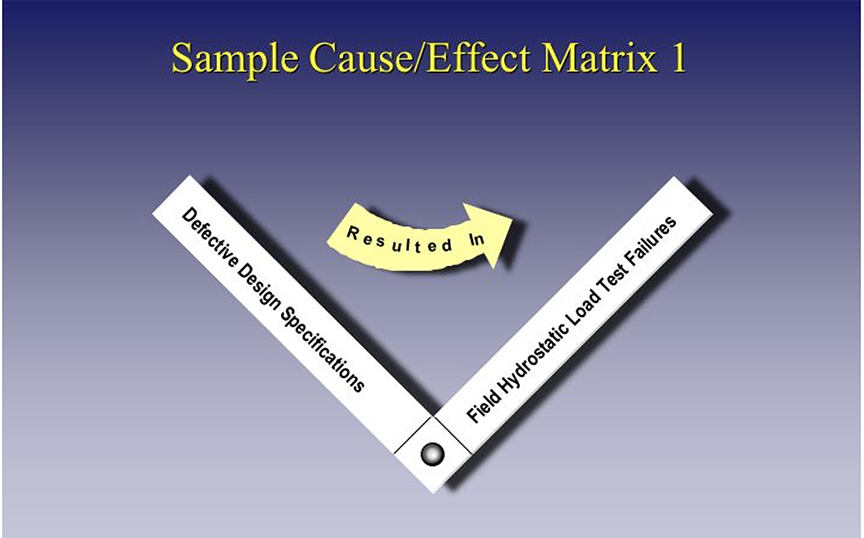

To demonstrate the cause-effect link of the issue entitlements to damages, Long International develops a Cause-Effect Matrix. To start with, a simple example of the cause-effect relationship is provided:

CAUSE:

“The Contractor produced defective design specifications.”

EFFECT:

“The hydrostatic load tests performed in the field failed. The project will be delayed.”

This simple concept is shown graphically in Figure 3.

Figure 3

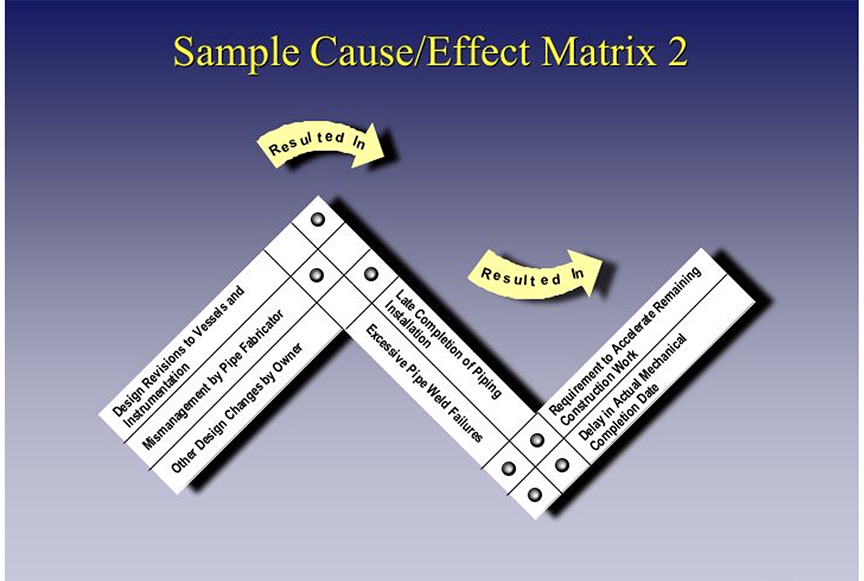

Of course, as causes and effects become increasingly more complex, say with primary and secondary causes and intermediate effects, the cause/effect matrix becomes more complex, as shown in Figure 4.

Figure 4

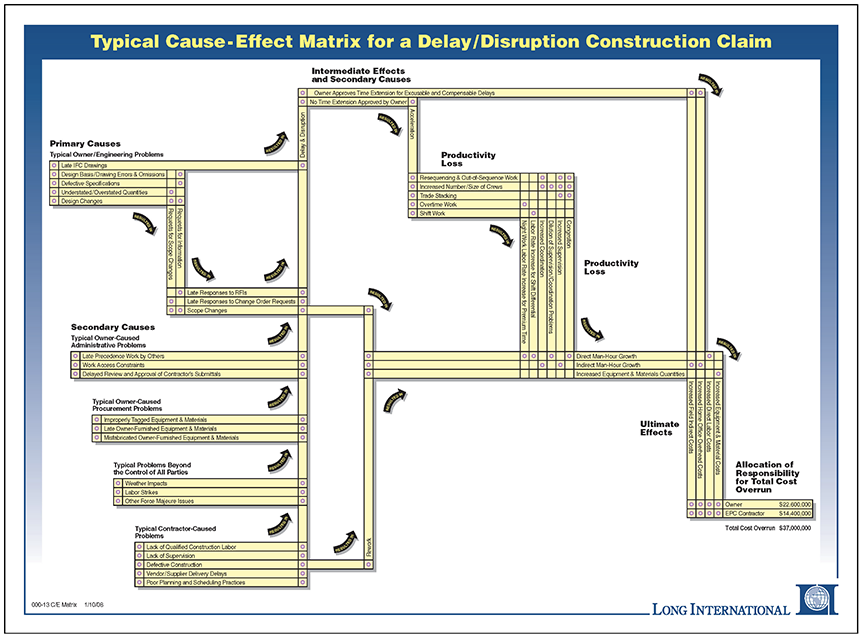

Ultimately, a Cause-Effect Matrix for a Contractor’s Delay and Disruption Claim that can show the link all the way from primary causes, through intermediate effects, to the amounts of damages allocated to each party becomes quite complex, as shown in Figure 5.

Figure 5

7.2.2 Cost Allocation Example

Once we are able to make the cause-effect link, we can sometimes allocate costs associated with poor Project Management to specific cost accounts. We use the “sometimes” qualifier because cost records that can make the association are not always kept. When adequate cost records are kept, however, the analysis and review of project management performance is relatively straightforward.

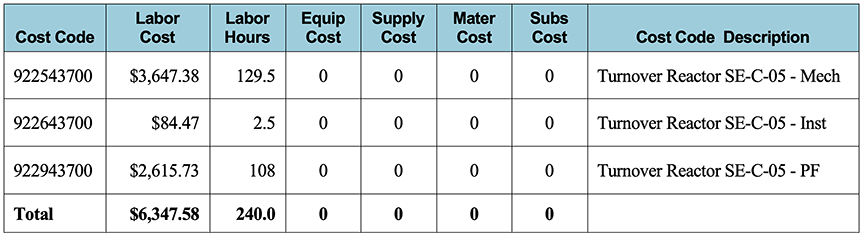

Using the example of delay to the turnover of a reactor shown above, the contractor kept records of its direct labor associated with that facility. A mechanical crew was assigned to the facility to be used for punch-list work, but was used only minimally while waiting for the results of the joint owner/contractor walk-down. This resulted in increased labor costs for that operation compared to the contractor’s budget.

When the work was finally completed, the contractor claimed for increased costs on the facility and blamed them on overzealous inspection and contrived delay by the owner. Over-zealous inspection notwithstanding, the contractor failed to take responsibility for the additional man-hours it caused and inappropriately applied the entirety of its overrun to a change request and claim.

From the contractor’s job cost records, Long International was able to identify the actual man-hour costs charged to the facility for the two week period when the contractor’s mechanical crew was underutilized by the delay to the walk-down.

The costs attributable to the contractor’s failure to properly execute his turnover plan could then be deducted from his claim.

8. EXAMPLES OF PROJECT MANAGEMENT PROBLEMS FROM ACTUAL CASES AND HOW THEY WERE ANALYZED

Shown below are some additional examples of Project Management problems that Long International has encountered and analyzed for its clients.

8.1 FAILURE TO PRODUCE THE PROJECT SCHEDULE ON TIME

An EPC contractor failed to produce a reliable Project Schedule in the time required by the Contract. The contractor blamed its failure to do so on everything but its own negligence, e.g., the owner was too picky, it didn’t get the Notice-to-Proceed when the contractor wanted it, and the ground was frozen so it had to wait for the ground to thaw.

The Contract provided a clear requirement for type, level of detail, and date required for development of the Project Schedule. The owner pointed out the contractor’s deficiencies by responding to several of the contractor’s submittals for approval, and ultimately, the schedule was approved late. The contractor blamed this delay on the owner, but a review of contemporaneous correspondence showed that the contractor was at fault. For example:

- Correspondence showed that the contractor’s own scheduler admitted that the schedule contained “inappropriate items.” In this case, this deficiency meant that the scope was not entirely covered and that some activities could not be completed in the time allotted.

- The contractor’s Project Manager admitted in an email that it was “faking” the schedule, i.e., the submittals were not based on full knowledge of what had to be done and how long it would take to perform the work.

- In an email, the scheduler admitted that the contractor could not achieve planned production with available manpower.

- The Project Manager admitted in an email that his Superintendent ignored the schedule, refused to provide progress updates, and “did planning in his head.”

As a result of these findings, the contractor’s claim of the owner delaying approval of his schedule was discredited, and the associated costs were not recoverable.

8.2 FAILURE TO PROVIDE COMMISSIONING PROCEDURES

An EPC contractor failed to provide complete commissioning procedures in the time required by the Contract. The contractor blamed this failure on the owner’s overzealous review of the procedures and its failure to approve them. Contemporaneous documents showed a different story, however:

- A written notice from the owner prior to any submittals pointed out that the contractor’s failure to provide the needed Commissioning Procedures on-time was going to result in a two-week delay to the start of commissioning.

- Additional owner correspondence pointed out that the commissioning sequences, when finally submitted for review, were impossible to execute because they did not consider the plant shutdown schedule. This resulted in further delay for rework of the procedures.

The contractor’s delay claim was discredited and it was unable to collect any of the additional commissioning costs for the two-week period attributed to its failure to provide the proper procedures in a timely manner.

8.3 BUILDING FROM THE WRONG DRAWINGS

An EPC contractor’s construction crew executed its work from drawings that were not “Approved for Construction.” This approval process was required according to the engineering procedures developed under the Contract. The drawings contained errors. The contractor had been warned of potential problems with the use of these drawings, but persisted in using them. This eagerness to use the drawings was due to the contractor’s field supervisors’ frustration with the drawings arriving late from its engineering department. Contemporaneous documents showed that the contractor was at fault:

- Correspondence from the owner shows that it warned the contractor on three occasions that workers were building foundations from drawings marked “Preliminary,” and that these drawings were incorrect.

- The use of unapproved and incorrect electrical conduit drawings resulted in the casting of incorrect foundation penetrations into a substation building.

- The superintendent’s log recorded that pipe rack drawings were changed in the field and the racks were constructed without engineering review. This resulted in the need to re-engineer and re-construct some of the pipelines on the pipe racks because the racks would not accommodate expansion loading in their as‑built condition.

As a result of these findings, the contractor’s claim for additional costs for rework and re-engineering on the above work was denied.

9. SUMMARY

The application of sound Project Management practices provides construction project stakeholders with the means to meet their objectives. When sound Project Management is lacking, it leads to delays and extra costs for all parties, typically resulting in a dispute of some consequence.

The application of sound Project Management principles on a project is not only the means to the project’s ends, but, during disputes, can also provide a level of defense against claims for delay and additional costs that were based on alleged management deficiencies. Demonstrating that you used sound Project Management practices, and that the other party didn’t, can help your side win disputes.

Long International employs a systematic and supportable methodology to review project management performance and assess problems caused by either of the contracting parties. This methodology includes:

- Analysis of Project Management requirements stated in the Contract;

- Analysis of the clarity of those requirements;

- Comparison of the Project Management requirements to those generally accepted in the construction industry, such as PMI and CII;

- Analysis of contemporaneous project documentation;

- Evaluation of the parties’ conformance to the Project Management requirements of the Contract and to those generally accepted in the construction industry;

- Development of cause and effect relationships between the project problems and the ensuing damages; and

- Allocation of the responsibility for Project Management problems to delay and damages calculations.

Long International has successfully used this methodology to support its expert opinions presented during dispute resolution cases.

About the Author

Truman D. King, P.E., was a Principal with Long International and retired in 2018. He has over 40 years of experience in engineering, procurement, and construction operations in the mining, oil and gas, refining, and real estate development industries. He has successfully completed assignments in the U.S., Middle East, and Europe. Mr. King was a Senior Project Manager for Worley Parsons, where he managed the Front End Engineering Design and acquisition of Process Design Technology for a US$500 million expansion of an oil refinery in the UAE to produce clean diesel fuel. He has also managed oil and gas, refining, power distribution, marine and other engineering projects and provided analysis of and resolution of contractor’s claims. Mr. King has extensive knowledge of the owner’s and contractor’s project management responsibilities on EPC turnkey projects. He has successfully analyzed claims involving mismanagement, defective engineering, delay, disruption, and disputed change orders. For further information, please contact Long International’s corporate office at (303) 972-2443.

1 A Guide to the Project Guide Management Body of Knowledge, ANSI/PMI 99-001-2004, PMBOK® Guide, section 1.2, What is a Project?

2 Construction Extension to the Project Management Body of Knowledge, PMBOK® Guide – 2000 Edition, a PMI Provisional Standard, 2003.

3 We recognize that there are other definitions of a Project, such as that shown in Cleland and King’s “Project Management Handbook” which states that a Project is “a group of tasks/activities, to be performed in a definable period, to meet a specific set of objectives.” Government agencies, union agreements, and others also provide definitions of what constitutes a Construction Project when it is necessary for their purposes.

4 Construction Extension to the Project Management Body of Knowledge, PMBOK® Guide – 2000 Edition, a PMI Provisional Standard, 2003, section 1.2.

5 From the American Heritage Dictionary of the English Language, 3rd ed. 1992.

6 PMBOK® Guide, section 1.2.1.3, Progressive Elaboration.

7 Ibid.

8 PMBOK® Guide, section 1.3, What is Project Management?

9 The actual Contract paragraph number precedes the name of each submittal.

10 PMBOK® Guide, section 1.3.2, The Project Management Knowledge Areas.

11 Construction Extension to the PMBOK® Guide, section 1.3.2, The Project Management Knowledge Areas.

12 See Figure 1.

13 The CPB describes itself as “a knowledge center that captures, organizes, and transfers business practice knowledge to Project stakeholders to help them excel in today’s rapidly changing business world.”

14 CMAA also states that “CM is often used interchangeably with Project Manager.” The CMAA is open to member “firms and individuals sharing a common interest in the promotion of construction management as a professional service.”

15 This is a subset of Project Integration Management as shown in the PMBOK® Guide.

Copyright © 2018 Long International, Inc.

ADDITIONAL RESOURCES

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE