February 16, 2026

Process Plant Terminology Part 4: Heat Transfer Processes

This is the fourth of nine blog posts that provide layman’s descriptions of process engineering terminology commonly encountered when describing industrial processes and associated equipment. The terms described herein can be found in use across a wide range of processing and manufacturing industries, including oil and gas, refinery, petrochemical, chemical, mining and mineral, wastewater treatment, and power generation industries.

The first post provided an overview of the various drawing types that are used to depict industrial processing and manufacturing plants, while the second post discussed general processing and manufacturing plant terminology. Posts three through nine discuss common unit operations and processing equipment typically found in industrial processing and manufacturing plants, with this fourth post specifically discussing heat transfer processes.

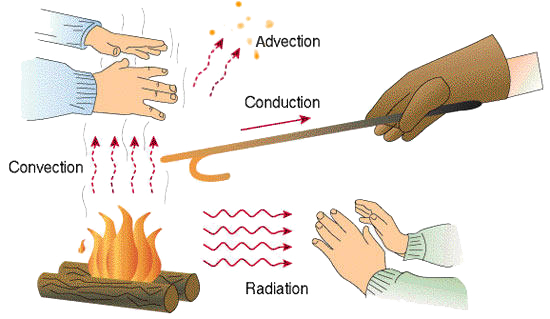

Heat transfer processes involve the transfer of energy from one gas or liquid stream to another and are typically driven by temperature differences in the gases or fluids, with energy flowing from the higher temperature stream to the lower temperature stream. As Figure 1 below shows, heat transfer can occur through one of four modes:1

- Advection: the transport of a fluid from one location to another that is dependent on the motion and momentum of the fluid, e.g., movement of warm air from one location to another due to wind (uncommon in process and manufacturing plants).

- Convection: the transfer of energy between an object and its environment due to fluid motion, e.g., hot air rising and cool air sinking due to differences in density (common in process and manufacturing plants).

- Conduction: the transfer of energy within one material or between objects that are in physical contact with each other, e.g., heating a pan on an electric stove (common in process and manufacturing plants).

- Radiation: the transfer of energy by the emission of electromagnetic radiation, e.g., the warming of the Earth by the sun (uncommon in process and manufacturing plants).

Figure 1: Heat Transfer Modes2

Heat transfer processes commonly found in processing and manufacturing plants include heat exchangers as well as heat transfer devices that facilitate specific phase-change processes such as condensers, evaporators (boilers), and evaporative coolers. Descriptions and examples of these common heat transfer processes are discussed below.

Heat Exchangers: Heat exchangers are devices used to transfer heat between one “hot” fluid and one “cold” fluid, with these fluids either in direct contact with each other (such as in a spray tower) or separated by a wall composed of a conducting material (more common, and the focus of the rest of this section of the post). Heat exchangers typically transfer heat between two gaseous streams (G/G heat exchangers), between two liquid streams (L/L heat exchangers), or between a gas stream and a liquid stream (G/L heat exchangers).

Heat transfer in these devices typically occurs by conduction (heat transfer through the wall material) and convection (heat transfer to/from the wall from/to the bulk fluids). An everyday example of this type of heat exchanger is the radiator in an automobile, shown below in Figure 2, where a hot liquid (coolant) passes through thin tubes and is cooled by air flowing over the outside of the tubes.

Figure 2: Automobile Radiator3

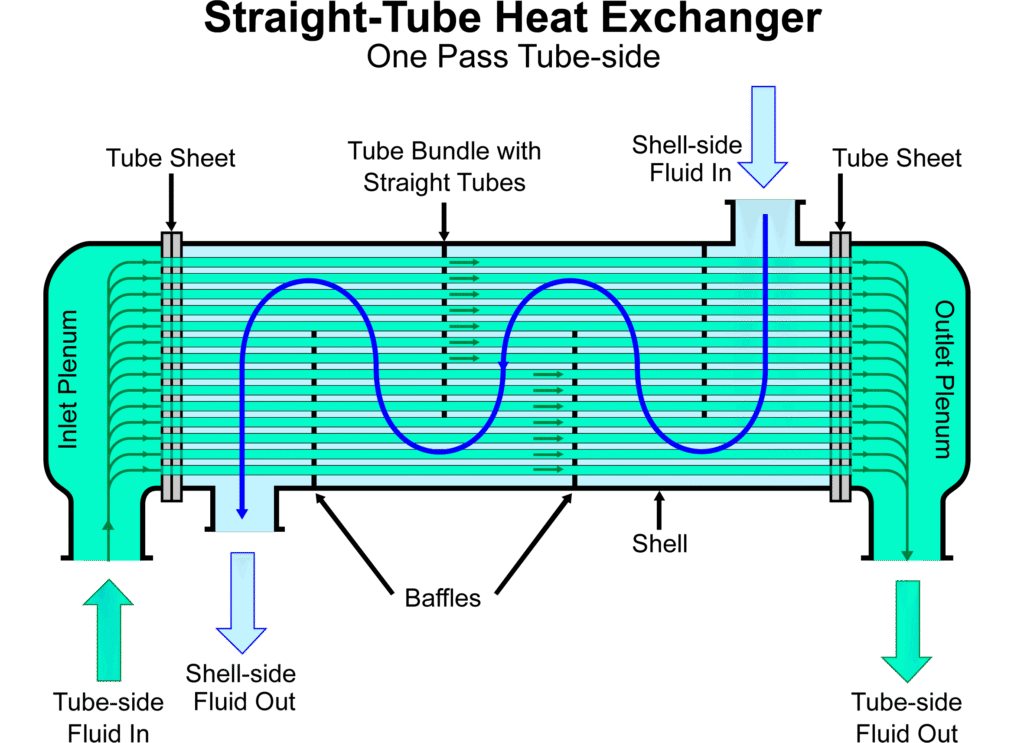

One of the most common heat exchanger types found in processing and manufacturing plants is the shell-and-tube heat exchanger. In shell-and-tube heat exchangers, one fluid flows inside tubes, and the other fluid passes over the outside of the tubes, with heat transferring from one fluid to the other through the tube walls, as shown below in Figure 3.

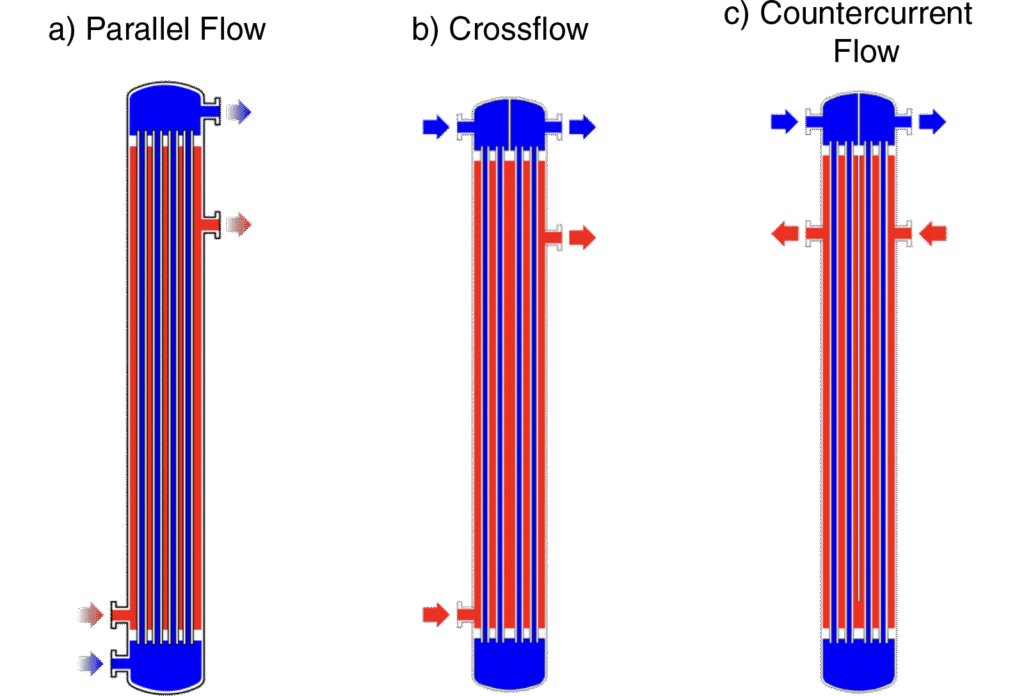

Other common heat exchanger types include: 1) plate heat exchangers, 2) cooling jackets, where chilled water is commonly used as a heat sink, and 3) heating jackets, where steam is commonly used as a heat source. Heat exchangers can be configured in either parallel flow, crossflow, or countercurrent flow (most efficient) arrangements, as shown below in Figure 4.

Figure 3: Cut-Away View of Typical Shell-and-Tube Heat Exchanger4

Figure 4: Common Heat Exchanger Configurations5

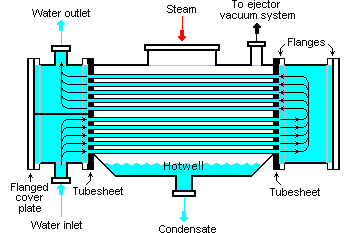

Condensers: A condenser is a type of phase-change heat exchanger that cools a vapor (gas) stream to condense it into a liquid. Condensers can be used to convert vapor into a liquid for further processing, such as in the condenser portion of a distillation column, or strictly for the purpose of heat rejection from a system, such as in refrigeration, air conditioning, or steam cycle (e.g., power generation) processes. Figure 5 below shows a cut-away view of a typical water-cooled condenser, which uses cooling water to condense steam into water for reuse in a steam-cycle process.

Figure 5: Cut-Away View of a Water-Cooled Surface Condenser6

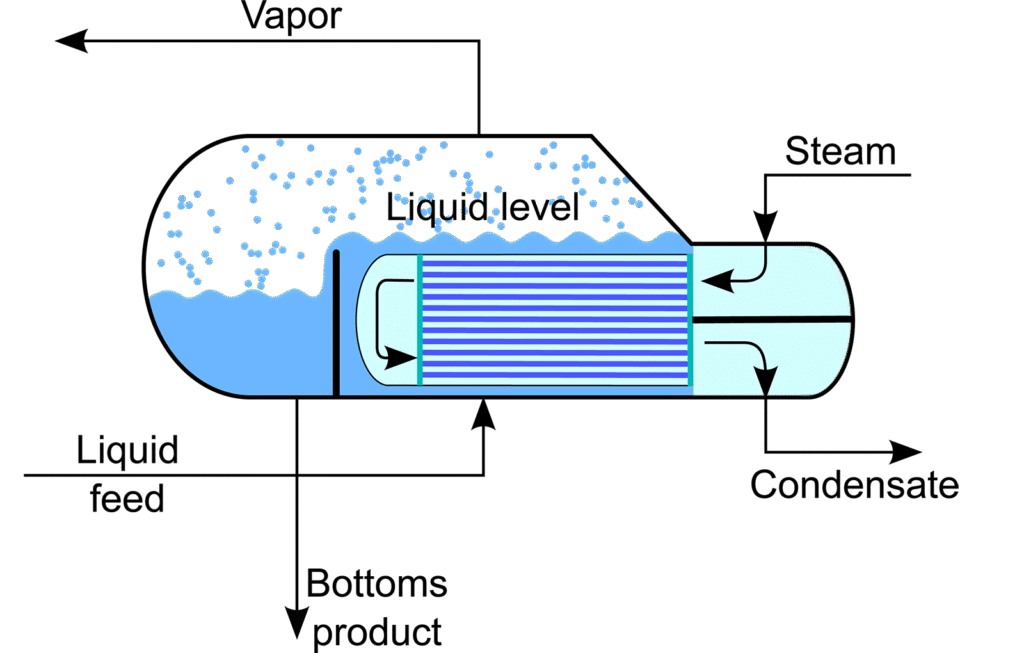

Boilers (Evaporators): A boiler is a type of phase-change heat exchanger that uses a hot medium (typically either flue gas, steam, or an electric heating element) to heat a liquid stream and evaporate (boil) it into a vapor. Boilers can be used to form steam for further utilization as a heating medium throughout the process, for use in a steam engine, or for use in steam-cycle processes (e.g., power generation plants). Boilers can also use steam to provide heat input to other unit operations, such as in the case of a distillation column reboiler. Figure 6 below shows a cut-away view of a typical distillation column reboiler, which uses a hot steam supply to vaporize a liquid feed.

Figure 6: Cut-Away View of a Distillation Column Reboiler7

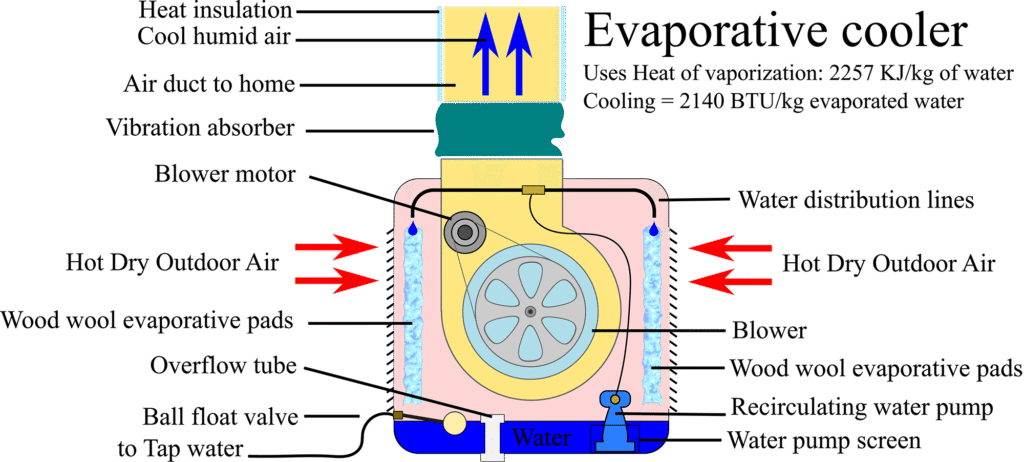

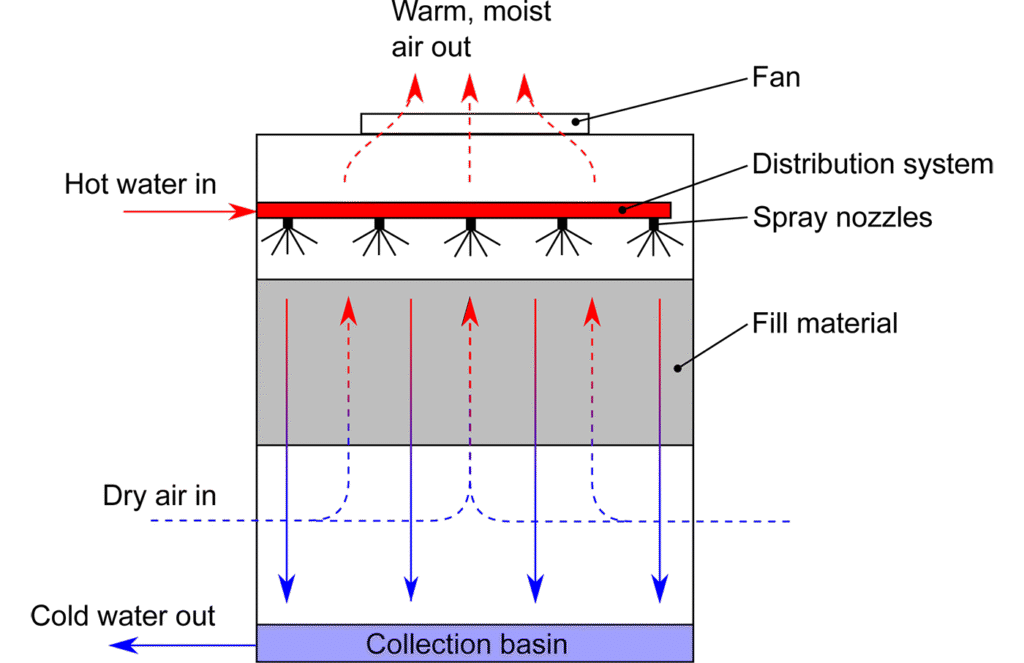

Evaporative Cooling: Evaporative coolers are another type of phase-change heat exchanger that make use of the latent heat of vaporization (i.e., the energy required to vaporize water) to cool either an incoming warm air stream or an incoming warm water stream. Typical examples of evaporative coolers include swamp coolers and cooling towers.

- In a swamp cooler, typically found in air conditioning applications, heat from incoming warm air is used to evaporate water, reducing the temperature and increasing the humidity of the outgoing air stream in the process. A typical swamp cooler is shown below in Figure 7.

- In a cooling tower, typically found in oil refinery, chemical plant, and thermal power plant applications, warm water is evaporated into a cooler air stream such that the latent heat of vaporization decreases the temperature of the outgoing water, as shown below in Figure 8.

Figure 7: Typical Swamp Cooler Diagram8

Figure 8: Typical Counterflow Cooling Tower9

1 “Heat transfer,” Wikipedia, accessed December 2, 2025.

2 “The four fundamental modes of heat transfer illustrated with a campfire” by Kmecfiunit, cmglee under CC BY-SA 4.0, accessed December 2, 2025.

3 “Water-air convective cooling radiator, made from aluminium, from a 21st-century car” by Bill Wrigley, public domain, accessed December 4, 2025.

4 “A shell and tube heat exchanger” by Sandstore de under CC BY-SA 4.0, accessed December 4, 2025.

5 Adapted from “Heat exchanger,” Wikipedia: a) “Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel flow)” by Ub under CC BY-SA 3.0, b) “Fig. 2: Shell and tube heat exchanger, 2-pass tube side (1–2 crossflow)” by Ub under CC BY-SA 3.0, c) “Fig. 3: Shell and tube heat exchanger, 2-pass shell side, 2-pass tube side (2-2 countercurrent)” by Ub under CC BY-SA 3.0. Accessed December 4, 2025.

6 “Typical water-cooled surface condenser” by Mbeychok, public domain, accessed December 4, 2025.

7 “Typical kettle reboiler used for industrial distillation towers” by H Padleckas under CC BY-SA 3.0, accessed December 4, 2025.

8 “Evaporative cooler illustration” by Nevit under CC BY-SA 3.0, accessed December 4, 2025.

9 “Counterflow diagram” by Edreher under CC BY-SA 3.0, accessed December 4, 2025.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

RECOMMENDED READS

Project and Construction Management Terminology

This post is part of a series defining industry terminology. This post addresses project and construction management.

READ

A Tale of Two Claims: Same Contract, Two Fates

The success of a claim often hinges not on what happened in the field, but how it was documented, analyzed, and communicated.

READ

The Role and Benefit of a Consultant in a Construction Project: Part 1

This is the first blog post in a two-part series on the role and benefit of a construction consultant.

READ