September 5, 2023

Differing Site Conditions (DSC): Types, Examples, and Claims

When a construction contractor encounters a subsurface or otherwise concealed site condition that differs from what was indicated in the contract or from what would normally be expected, the condition encountered is often referred to as a “differing site condition.”

Examples of differing site conditions (DSC) may include unforeseen subsurface conditions, different soils, hidden rock, excessive groundwater, harder rock, higher subsurface rock elevations, hidden structures, a higher water table, buried unsuitable fill, concealed preexisting conditions, or other unanticipated conditions. This is the first of two blog posts about DSC. It explains DSC Types 1, 2, and 3 and DSC claims. The second post will explore contract language and paths by which a contractor might recover from DSC.

DSC were originally called “changed conditions.” Aboveground work or situations that involve renovation or rehabilitation of existing works may generate changed conditions claims. For example, if an upstream contractor creates hardship for performance of downstream work, or if the error of a third party damages equipment, a changed condition claim may result. The term “changed condition” may be a misnomer for DSC because DSC generally do not refer to a change but to a condition that existed when the contract was executed but was not anticipated.

The prospects for a contractor to recover after encountering DSC depend on:

- The extent of positive representations of anticipated subsurface conditions that the owner made;

- The extent to which encountered conditions differed materially from those represented;

- The extent to which the contractor could have anticipated or observed the different conditions by a site visit, previous experience in the geographic area, etc.;

- The extent to which the contractor documented its assumptions regarding site conditions affecting the work as a basis of its cost estimate;

- The owner’s knowledge of the conditions actually encountered; and

- The extent to which the contractor provided written notice to the owner when DSC were encountered.

Over the years, the extent to which a contractor can recover monetary compensation because of increased complexity of work due to unexpected subsurface conditions has slowly evolved. The landmark in this evolution has been the use of standard Form 23A in federal contracts (see Federal Acquisition Regulation (FAR) at 48 C.F.R. ¶52.236-2), which allows contractors equitable recovery for DSC. Other contract forms, such as those by AIA, AGC, EJCDC, ConsensusDocs 200 Document, and FIDIC, contain variations of DSC clauses. At the other end of the spectrum, however, some private owners employ exculpatory language denying any responsibility for subsurface conditions in a contract absent a differing site condition clause.

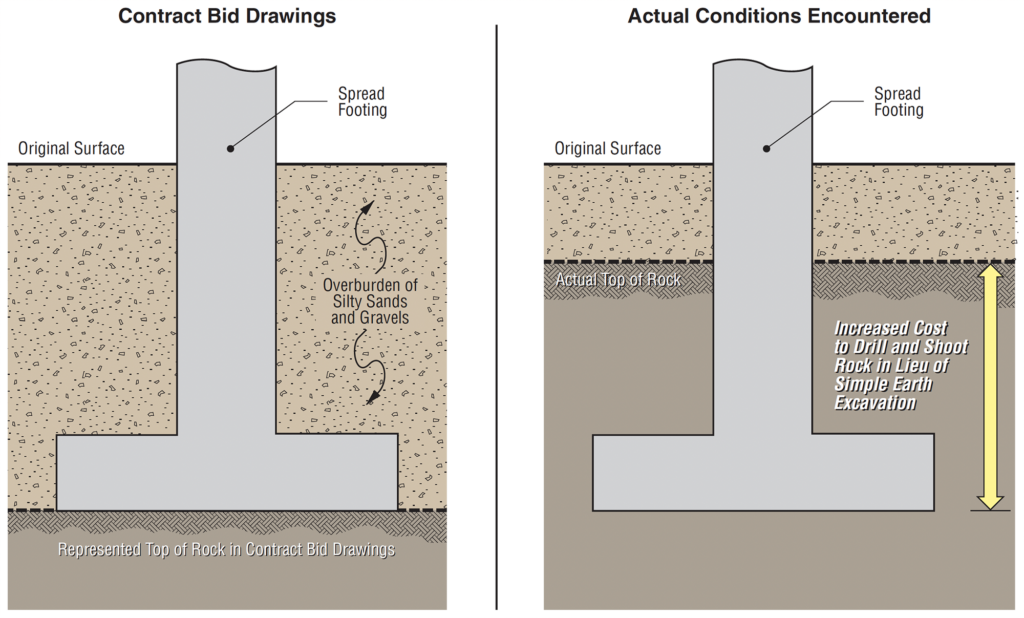

DSC are often classified as either Type 1 (I), Type 2 (II), or Type 3 (III). Type 1 differing site conditions are generally defined as ones in which actual physical (subsurface or latent) conditions encountered at the site differ materially from the conditions represented in the contract documents. For example, see Figure 1 below.

Figure 1

Example of a Type 1 DSC

For Type I DSC, the contractor must establish that the conditions encountered were physical, that the conditions were subsurface or latent, that they were encountered at the site, and that there was a material difference between the conditions encountered and the conditions indicated in the contract. In addition, the contractor may be required to prove that it relied on the information presented in the contract, that the actual conditions encountered were unknown, that because of this reliance and the DSC encountered, the contractor’s cost and potentially time of performance increased, and that the contractor provided proper notice to the owner. Contractors frequently request time extensions resulting from DSC. Most DSC clauses provide an adjustment of the contract time if the problem affects the time required for completion.

Type 2 DSCs are defined as ones in which physical conditions encountered at the site differ materially from the conditions normally encountered and generally recognized to exist, given the nature and locale of the work. The major difference between Type 1 and Type 2 differing site conditions is that in Type 2 DSC, the owner has not made any substantive representations or indications in the contract documents relative to anticipated site conditions. Because the contractor cannot compare actual conditions to the contract documents, the contractor’s burden of proving Type 2 DSC increases significantly.

In addition to the components previously identified that must be established to prove entitlement for Type 1 DSC, the contractor seeking a Type 2 DSC claim has the added burden of proving what conditions are recognized as usual at the site, and that the conditions encountered were unusual.

Type 2 DSC claims have been denied when one of the following conditions has been present:

- The condition was common to structures built during a particular era even though the contractor was not accustomed to the existence of the condition.

- The condition was subsurface water, and the site was located near a large body of water.

- The condition was an obstruction in a customary location.

- The contractor had experienced the condition on similar projects.

- The condition should have been known from a review of the boring logs.

- The condition was normal for the geographic area.

A Type 3 DSC clause typically assigns the risk of handling unanticipated hazardous materials to the owner. An increasing trend in the public rail transportation industry is to identify in the contract and bidding documents the increased potential for encountering hazardous materials during site dewatering and excavation. Portions of light, heavy, and commuter rail lines are often situated on former freight lines where tank car leakages have occurred over many years and creosoted track ties were used with associated creosote leachate.

The potential for Type 3 DSC claims may be limited to the types of hazardous waste materials not accepted by regional certified disposal sites. A similar procedure could be established for contaminated water, where the construction contractor would provide for a holding tank and onsite treatment facilities.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

RECOMMENDED READS

Differing Site Conditions

This article covers contractual representations, types of differing site conditions, the contract absent a differing site conditions clause, and owner defenses.

READ

Construction Claim Types for Contractors

U.S. federal and state courts recognize 19 basic construction claim entitlements for a contractor’s recovery of damages.

READ

Definitions of Construction Claim Types for Contractors

This post summarizes the definitions of the 19 construction claim types that may apply to a contractor’s and subcontractor’s recovery of time and costs.

READ