Calculating the As‑Built Critical Path

This paper discusses procedures to ensure that the as-built driving lag values are determined objectively to avoid inconsistent or subjective assessments in as-built critical path calculation.

ABSTRACT

The as-built critical path of a project schedule can be determined by developing As-Built Calculation Schedules for each relevant schedule analysis period. An As-Built Calculation Schedule removes verified actual dates from the schedule and revises the activity and lag durations to be equal to the actual durations. The creation of the As-Built Calculation Schedule enables the CPM scheduling software to then calculate the as-built critical path. To properly create an As-Built Calculation Schedule, it is necessary to determine the driving predecessor relationships in the as-built schedule when there are multiple predecessors to an activity. If a predecessor is not driving, the actual lag duration should be reduced to the originally planned lag value to create float in the As-Built Calculation Schedule. If the determination of driving predecessor relationships is not performed, all activities in the As-Built Calculation Schedule would have zero total float and would be equally critical. This paper presents procedures to ensure that the as-built driving lag values are determined objectively to avoid inconsistent or subjective assessments in calculating the as-built critical path.

1. INTRODUCTION

The determination of the as-built critical path of a project is of great importance for the analysis of schedule delay claims. It is commonly accepted by scheduling practitioners that the critical path of a construction project is dynamic and may change over time such that the as-built critical path may be different from the as-planned critical path. Many contracts require that the Contractor demonstrate that the claimed delay events impacted the project completion date, which is driven by the as-built critical path or longest path to completion. The calculation of the as-built critical path is also essential for performing collapsed as-built or but-for schedule analyses as described in AACE International Recommended Practice No. 29R-03 on Forensic Schedule Analysis, Method Implementation Protocols 3.8 and 3.9, for modeled, subtractive delay analyses. However, as acknowledged in RP No. 29R-03, Subsection 4.3.C, there presently is no consensus among practitioners regarding a common set of logic rules for accurately determining the as-built critical path because actual dates override float values. This paper presents proposed guidelines for calculating the as-built critical path.

2. VERIFYING THE ACCURACY OF THE AS-BUILT SCHEDULE

As-built critical path method calculation requires that an accurate as-built schedule first be developed. To verify the reliability of the as‑built schedule, contemporaneous project records should be reviewed to confirm the accuracy of the actual dates. Any necessary corrections to actual dates and progress percent complete values should be documented based on contemporaneous project data such as daily reports, monthly progress reports, meeting minutes, payment applications, drawing logs, submittal logs, superintendent logs, and progress photographs. Source Validation Protocols 2.2 and 2.3 of AACE International Recommended Practice No. 29R-03 on Forensic Schedule Analysis provide procedures for utilizing as-built schedule source documentation to reconstruct, validate, and rectify as-built schedules and schedule updates.

3. CONVERTING AS-PLANNED LOGIC TO AS-BUILT LOGIC

After the as-built schedule dates are validated and rectified, it is necessary to review the reasonableness of the as-built schedule logic. Work activities may have been performed out-of-sequence from the as-planned logic. Method Implementation Protocol 3.8.K.2 of AACE International Recommended Practice No. 29R-03 on Forensic Schedule Analysis provides procedures for converting as-planned logic to as-built logic. In some cases, the actual sequence of work and the relationships between activities may be different from the planned sequence of work and activity relationships. Therefore, the logic relationships between the activities in the as-built schedule at the end of each window may be different from the planned logic relationships at the start of the window. Accordingly, if the actual sequence of work indicates that different logic relationships between activities are warranted, the schedule logic should be adjusted to represent the as-built conditions and the logic revisions should be documented.

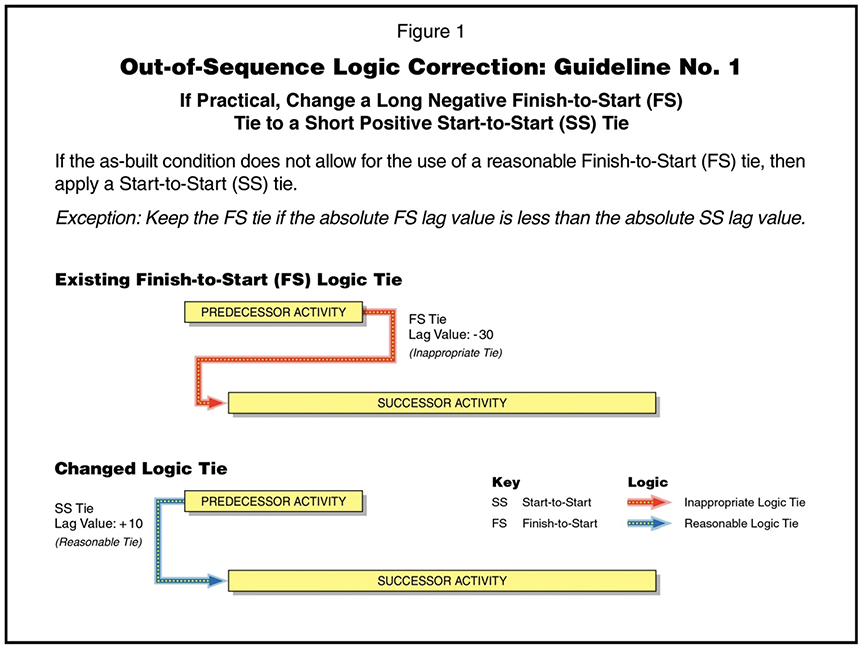

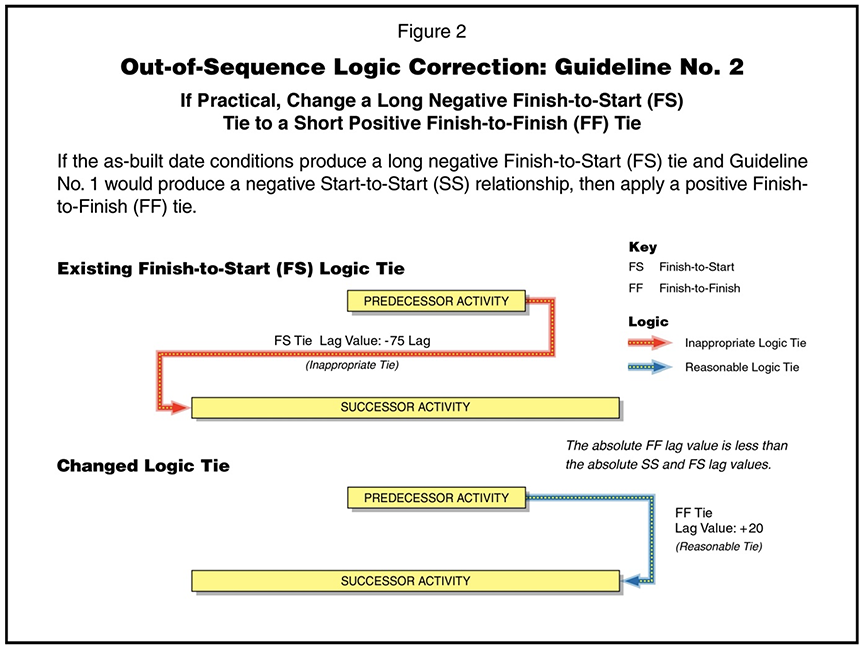

Activities that have out-of-sequence logic with long negative lag values that were completed or were in-progress within each schedule analysis window should be identified. Guidelines for correcting out-of-sequence logic with long negative lags are detailed in the following paragraphs.

Often large negative lag relationships may exist in the as-built schedule that stem from the as‑planned schedule logic. To more accurately model the actual work sequences in each schedule analysis window, adjustments should be made to the as-built schedule logic to replace out-of-sequence logic and large negative lag values (e.g., greater than 15 work days) with more reasonable logic ties. While the Contractor’s original logic should be utilized wherever possible, the following guidelines are recommended when analyzing and rectifying out-of-sequence logic resulting from the as-built date conditions.

Guideline No. 1: If the as-built date conditions produced a long negative Finish-to-Start (FS) relationship, where practical, change the long negative FS relationship to a short positive Start-to-Start (SS) relationship, as shown below in Figure 1.

Guideline No. 2: If the as-built date conditions produced a long negative FS relationship and Guideline No. 1 would produce a negative SS relationship, where practical, change the long negative FS relationship to a short positive Finish-to-Finish (FF) relationship, as shown below in Figure 2.

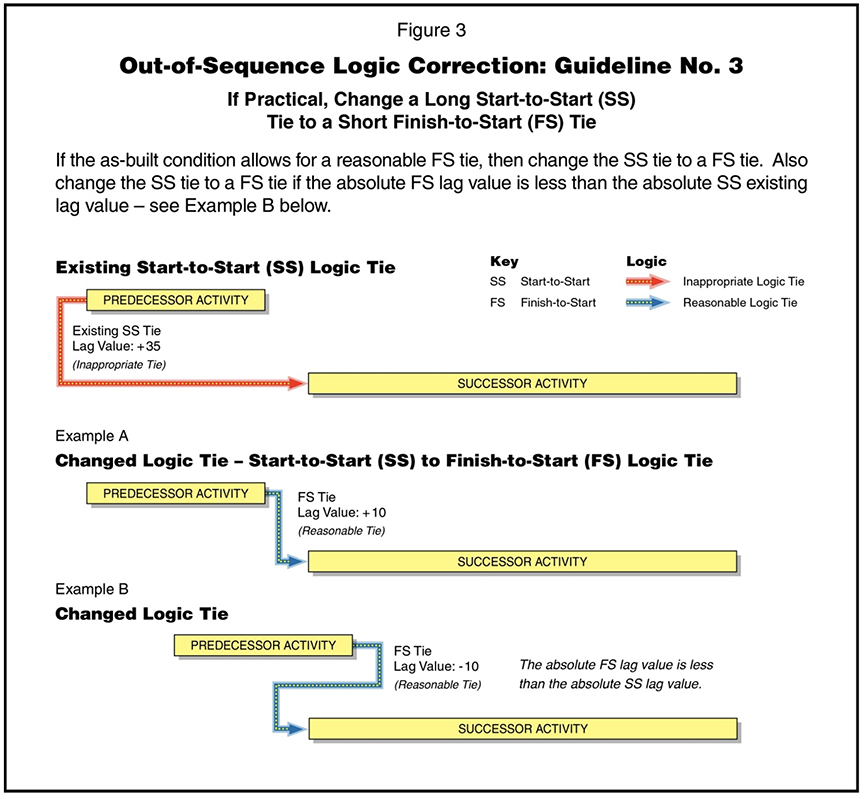

Guideline No. 3: If the as-built date conditions produced a long SS relationship and the as-built conditions allow for a reasonable and shorter FS relationship, then, where practical, change the long SS relationship to a short FS relationship. For example, a SS +35 day relationship between two activities in the as-built condition could be changed to a FS +10 day relationship between the same predecessor and successor activities, as shown below in Figure 3, Example A. In other cases, a short negative FS lag may be more realistic for modeling actual work sequences than a long SS lag, as shown below in Figure 3, Example B.

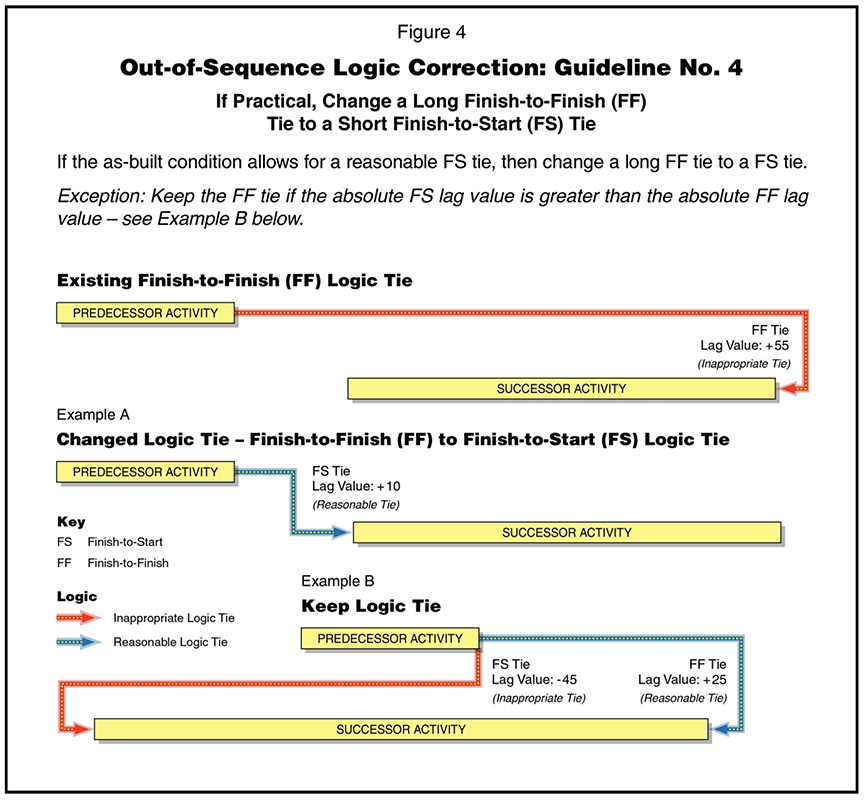

Guideline No. 4: If the as-built date conditions produced a long FF relationship and allow for a reasonable FS tie, then, where practical, change the FF relationship to a FS relationship. For example, a FF +55 day relationship between two activities in the as-built condition could be changed to a FS +10 day relationship between the same predecessor and successor activities, as shown below in Figure 4, Example A. If the as-built conditions would produce a long negative FS relationship, for which the absolute value of the lag duration is greater than the positive FF lag value, then the existing FF relationship should be retained, as shown below in Figure 4, Example B.

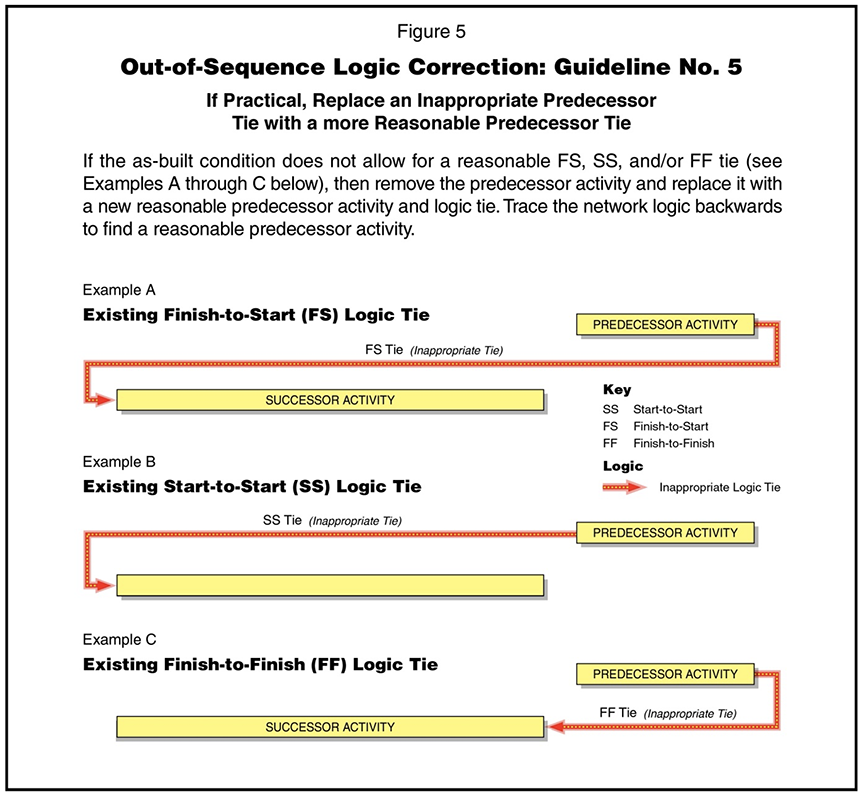

Guideline No. 5. If the work activities were performed significantly out-of-sequence and the as‑built date conditions do not allow for a reasonable FS, SS, and/or FF tie, then remove the inappropriate predecessor logic and replace the relationship with a different, more reasonable predecessor activity relationship. To select a more reasonable predecessor activity to replace the inappropriate predecessor, where practical, trace the network logic preceding the inappropriate predecessor to identify a more appropriate predecessor earlier in the logic chain and then reapply Guidelines 1 through 4 to determine the appropriate logic tie.

When converting the as-planned logic to the as-built logic, it is generally preferred to select logic relationships with shorter lag durations rather than longer lag durations, based on a comparison of the absolute values of the lag durations. Furthermore, physical work flow restraints driving the actual design, procurement, construction, and commissioning activity sequences should govern the rectification of the as-built logic. The purpose of the as-built logic rectification is to realistically model the work sequence relationships for how the project was actually built.

When making the above as-built logic adjustments, it is necessary to identify and correct any open-ends created while correcting the out-of-sequence logic. The logic should be checked in the As-Built Calculation Schedule to ensure that no activities have open-ends. If new open-ends are identified, appropriate logic ties should be added to close the open-ends.

Finally, if Primavera or similar software is used to develop the as-built schedule and the Progress Override calculation mode is utilized, it may be necessary to identify and correct the logic for any activities with effective open-ends due to Progress Override. The Progress Override calculation mode ignores logic relationships and allows an activity with progress to continue even if its predecessors have not finished. Based on the as‑built dates and calculated progress spanning a schedule window data date, some task activities may have effective open-ends due to the Progress Override schedule calculation setting. When schedule activities are worked out-of-sequence, the Progress Override feature nullifies the predecessor-to-successor logic for activities that started out-of-sequence, and then allows the late finish dates for these activities to slip to the completion date of the latest finishing activity for the project. This condition is not realistic or reasonable and the resulting late dates and corresponding float values are incorrect. Therefore, activities with effective open-ends due to the Progress Override calculation mode for each analysis window should be identified and appropriate logic adjustments should be made to eliminate the open-ends.

The specific logic modifications performed to correct any out-of-sequence logic or to close effective open-ends in each schedule analysis window should be documented in conjunction with rectifying the as-built logic. Any assumptions made and procedures followed while correcting the as-built logic should be documented to ensure consistency and avoid subjectivity during the rectification process.

4. CREATING AN AS-BUILT CRITICAL PATH CALCULATION SCHEDULE FOR EACH SCHEDULE ANALYSIS WINDOW

After verifying the accuracy of the as-built schedule dates and correcting any out-of-sequence as‑built logic ties, an As-Built Calculation Schedule can be developed for each schedule analysis window. A windows-based analysis is often preferred over a single analysis of the entire project duration to better account for how the critical path changed over time. The purpose of the As‑Built Calculation Schedule is to calculate the as-built critical and near-critical paths and as‑built float values. The selection of the schedule analysis windows is typically based on the availability of the schedule updates, key contractual events and issues, changes in the critical path, and cost and time considerations.

In commonly used scheduling software, such as Primavera, actual dates override the schedule logic and the actual start and finish dates of activities become fixed regardless of the logic when actual dates are input to record as-built progress. Therefore, the as-built critical path and float values, which can only be determined from the schedule logic, are not provided by the software calculations for the work that was performed prior to the data date. The critical path and float values are only displayed for work yet to be performed after the data date.

To create an As-Built Calculation Schedule, it is necessary to destatus the as-built schedule by removing the actual dates from the activities in progress during the schedule analysis window and inputting actual activity and lag durations and progress percent complete values. The start and finish dates in an As-Built Calculation Schedule are driven by as-built schedule logic, as‑built activity durations, and as-built percent complete values for the activities in each schedule analysis window. The as-built logic, driving lag values, actual durations, and percent complete values are input into the As-Built Calculation Schedule such that they generate the same early start and early finish dates for activities as they actually started and finished during each window. The As-Built Calculation Schedule also calculates the same forecasted start and finish dates for activities beyond the end of the schedule analysis window.

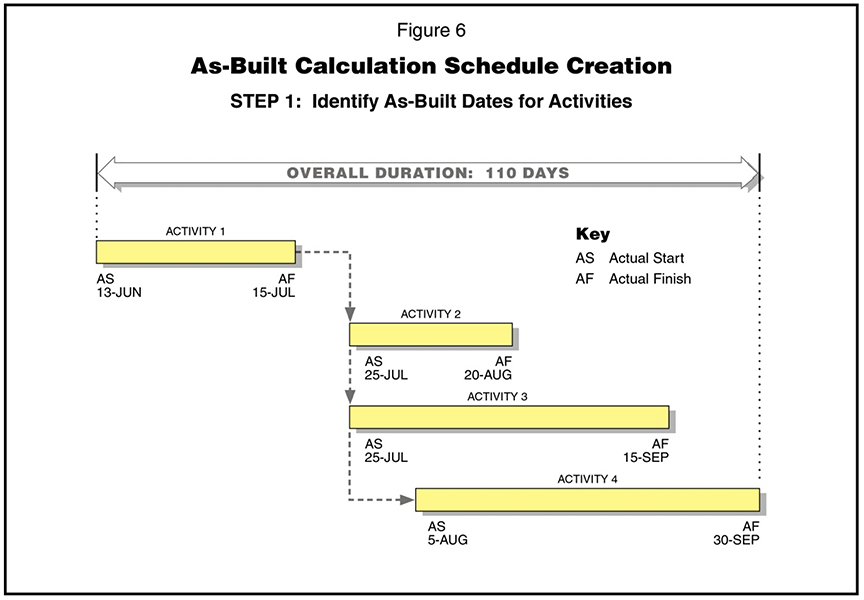

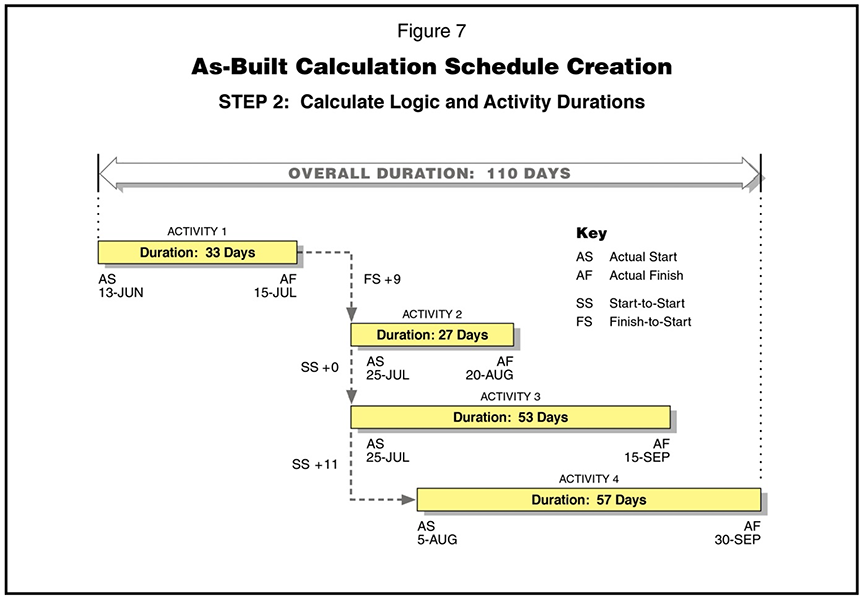

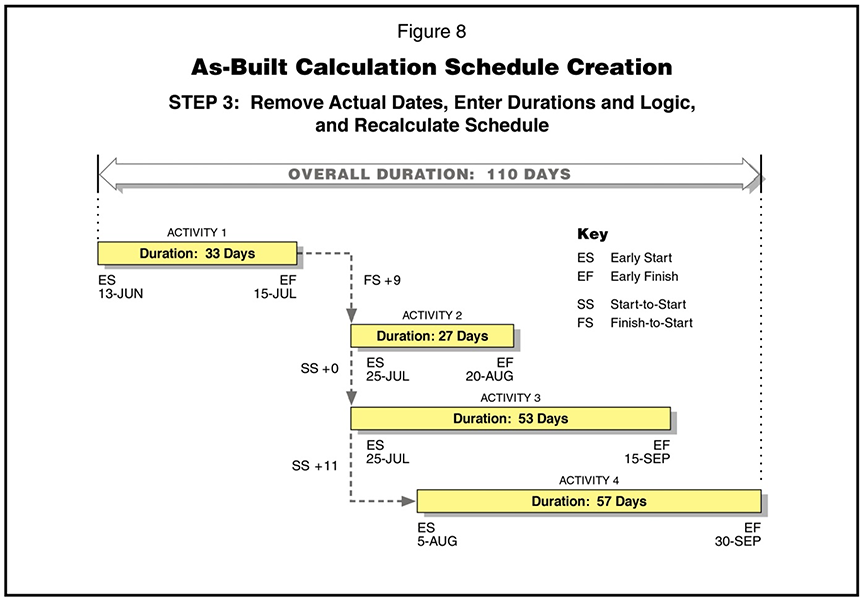

Figures 6, 7, and 8 below summarize three basic steps for creating an As-Built Calculation Schedule. In Figure 6, Step 1 involves the identification of the as-built dates for the activities within the schedule analysis window.

In Figure 7, Step 2 involves the calculation of the as-built activity and lag durations for the activities within the schedule analysis window.

In Figure 8, Step 3, the actual dates are removed and the actual activity and lag durations and percent complete values are input into the schedule such that the scheduling software calculates the start and finish dates of the activities to be the same as the as-built start and finish dates. The removal of the actual dates is referred to as destatusing the schedule.

5. THE DESTATUSING PROCEDURE

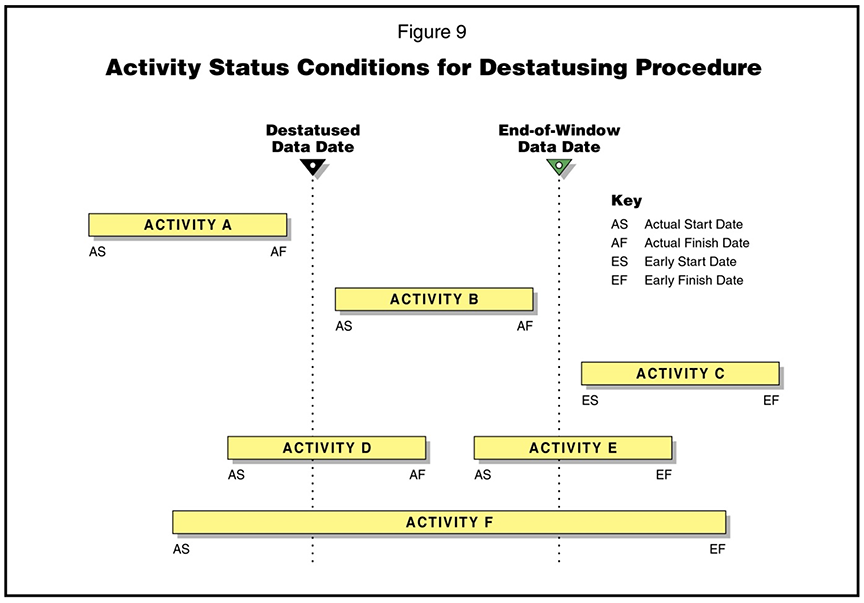

The schedule is destatused by moving the data date in the As-Built Calculation Schedule from the end of the schedule analysis window to the beginning of the schedule analysis window. Figure 9 below presents the potential activity date conditions, where the schedule being analyzed contains unfinished activities and the analysis period begins later than the Project Start date.

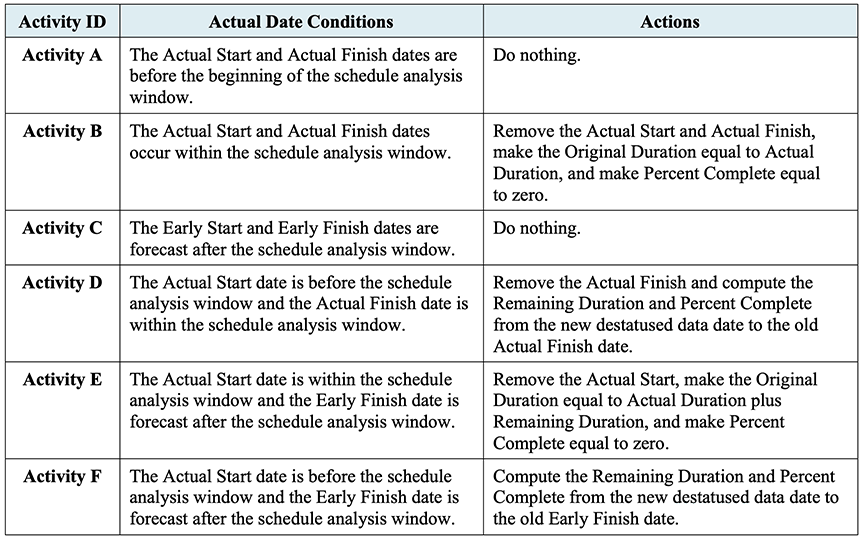

The actual date conditions and corresponding actions for destatusing schedule activities occurring within each schedule analysis window are summarized in Table 1 below.

Table 1

Actual Date Conditions and Corresponding Actions for Destatusing Schedule Activities

All actual dates prior to the destatused data date are not changed and this portion of the schedule remains statused with actual dates. All forecast dates after the end-of-window data date also remained unchanged.

As noted in Table 1, the percent complete and remaining duration values need to be computed for activities having the date conditions of Activities D and F. Source Validation Protocol 2.3.D.1.a of AACE International Recommended Practice No. 29R-03 on Forensic Schedule Analysis discusses the “hindsight” method for calculating remaining durations based on actual dates and durations. The computed percent complete and remaining duration values should be input into the As-Built Calculation Schedule to maintain the as-built schedule activity start and finish dates.

At this point in the development of the As-Built Calculation Schedule, the original and remaining durations of all activities are correctly adjusted but the lag durations for each relationship have not yet been adjusted to maintain the as-built schedule activity start and finish dates. The early dates of the activities that have been converted from actual dates should match the as-built schedule dates. The goal is to quantify the lag durations required to drive the original as-built schedule dates and model this in the As-Built Calculation Schedule. Each predecessor relationship must be reviewed for each activity that used to have an actual date but no longer does.

It is then necessary to compute the actual lag duration by converting the beginning date for the lag into a workday number and the ending date for that lag into a second workday number and subtracting the two workday values. The following formulas summarize the actual lag duration calculations:

EQUATION 1:

Finish-to-Start Lag Duration = Successor Start Date – Predecessor Finish Date – 1 day

EQUATION 2:

Start-to-Start Lag Duration = Successor Start Date – Predecessor Start Date

EQUATION 3:

Finish-to-Finish Lag Duration = Successor Finish Date – Predecessor Finish Date

EQUATION 4:

Start-to-Finish Lag Duration = Successor Finish Date – Predecessor Start Date + 1 day

If using Primavera scheduling software calendar rules, the Activity Calendar for the predecessor activity should be used in performing the conversion of an activity date to a workday number. If the activity date is an Actual Start and falls on a non-workday, then the next higher workday is used. If the activity date is an Actual Finish and the date falls on a non-workday, then the next lower workday is used. The calculated actual lag durations are then input into the As-Built Calculation Schedule.

After performing the actions in Table 1, the resulting As-Built Calculation Schedule will have a new data date at the beginning of the schedule analysis window and the calculated start and finish dates of each activity within the analysis period will be adjusted to match the actual conditions shown in the as-built schedule.

6. DRIVING PREDECESSOR LAG DETERMINATIONS

To properly create an As-Built Calculation Schedule, it is necessary to determine the driving predecessor relationships in the as-built schedule when there are multiple predecessors to an activity. If a predecessor is not driving, the actual lag duration should be reduced to the originally planned lag value to create float in the As-Built Calculation Schedule.

The actual lag duration for each relationship within the schedule analysis window should be calculated but it is not necessary to apply all of the actual lags to all relationships in the As‑Built Calculation Schedule. If all lags in the As-Built Calculation Schedule are converted into the actual lags, the activity dates in the As-Built Calculation Schedule would be correct but all activities would have zero Total Float and the entire schedule network would be on the as-built critical path.

To determine the “driving” relationship, the shortest duration variance between the planned lag and the actual lag for each predecessor to a successor should be calculated. In other words, it is necessary to identify the predecessor tie that most probably caused the successor activity to start or finish based on the “closest” predecessor to the successor activity with consideration for planned lag durations. If the variance between the planned lag and the actual lag is negative, then the relationship must become a driving relationship to maintain the correct as-built dates in the As-Built Calculation Schedule. If multiple relationships have the equally shortest variance between the planned (Contractor defined) lag and the actual lag, then all relationships with the equally shortest variance are designated as driving relationships.

The actual lag should only be input for driving relationships and the non-driving lag durations should be left as originally input in the Contractor’s plan. To ensure that the As-Built Calculation Schedule driving lag values are determined objectively, and to avoid inconsistent or subjective assessments in developing the as-built critical path, the following procedure is used:

- When there are multiple predecessor activities to a successor activity, the predecessor with the smallest variance between the actual lag and the planned lag is used as the driving predecessor and all other positive lags for predecessors to the same successor are reset to the planned lag value contained in the verified as-built schedule. The planned lag typically is the lag value input contemporaneously by the project scheduler, or may be a lag duration that has been rectified by the schedule analyst based on documented facts regarding the reasonable lag duration required between two activities.

- If a successor activity has only one predecessor, then the actual lag value must be used as the driving lag value to correctly calculate the successor activity dates to correspond with the verified as-built schedule dates.

- If two or more predecessors to an activity are equally driving, meaning that they have equal variances between the actual lag and planned lag, then each predecessor should be assigned the required driving lag values such that they equally drive the successor activity dates.

- All actual negative lags must remain negative to retain the original dates in the verified as-built schedule.

- If a predecessor is not driving, then the actual lag duration should be reduced to the planned lag value in the verified as-built schedule to create float in the As-Built Calculation Schedule.

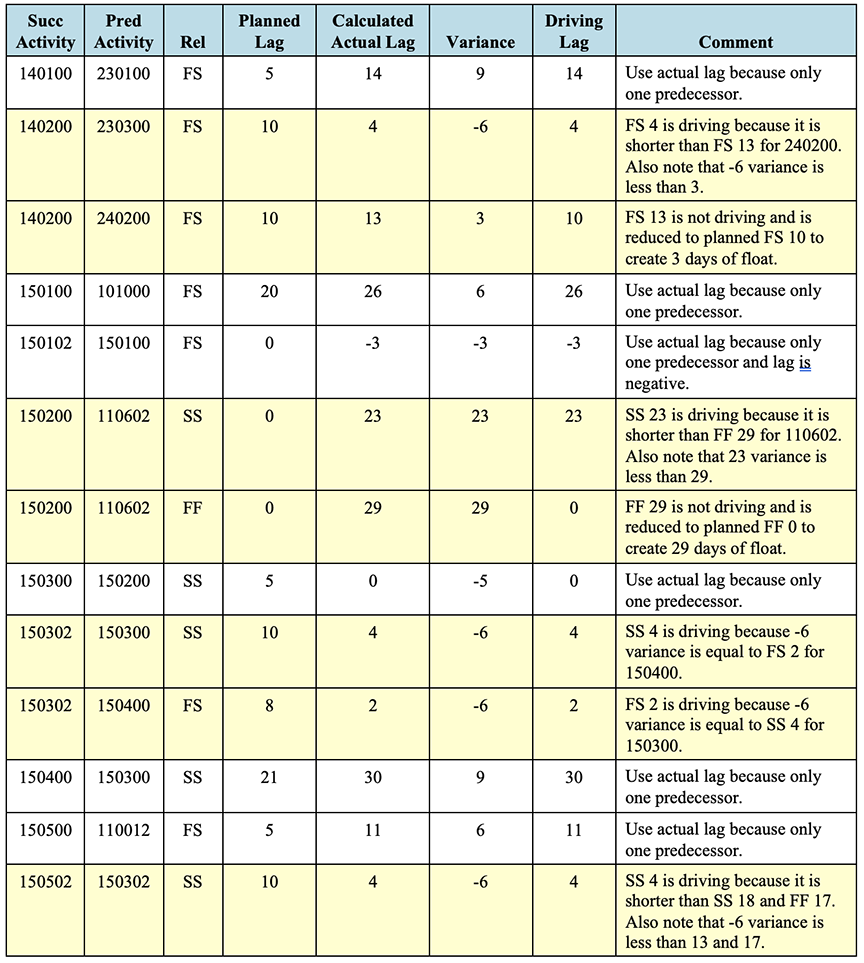

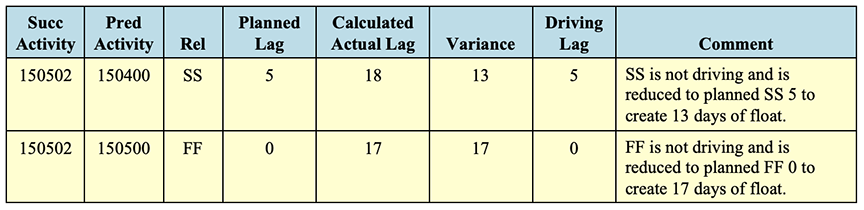

Table 2 below presents examples of driving lag duration calculations. Note that the smallest value in the variance column for a group of predecessors determines which relationship is driving. Negative variances are treated as being smaller or shorter than positive variances. Rows in Table 2 are shaded in yellow for successor activities with multiple predecessors.

Table 2

Sample Driving Lag Calculations

In summary, when there are multiple predecessor activities to a successor activity, the predecessor with the smallest variance between the actual lag and the planned lag should be used as the driving predecessor and all other positive lags for predecessors to the same successor are reset to the planned lag duration. All actual negative lags must remain negative to retain the original dates in the original schedule.

If two or more predecessors to an activity are equally driving, meaning that they have equal variances between the actual lag and planned lag, then assign the required lag durations to each predecessor such that they equally drive the successor activity dates. If a predecessor is not driving, reduce the actual lag duration to the planned lag value to create float in the As‑Built Calculation Schedule.

7. HOW TO CALCULATE AS-BUILT CRITICAL PATHS AND NEAR-CRITICAL PATHS AND REVIEW FOR REASONABLENESS

After the driving predecessor relationships are determined and input into the As-Built Calculation Schedule, the schedule is recalculated to determine the float values and as-built critical and near-critical paths for activities that were completed or were in-progress during the window.

To ensure that the As-Built Calculation Schedule was developed properly, a variance analysis should be performed for all activities by comparing the start and finish dates in the As‑Built Calculation Schedule to the verified as-built schedule to ensure that there are no date variances. If date variances are found when performing this comparison, it is necessary to identify the date inconsistencies and document the reasons for any acceptable variances. Date variances may arise from activities having different calendars or when the as-built date falls on a non-work day as defined by the schedule calendar.

Finally, the calculated critical and near critical paths from the data date at the start of the window through Project Completion should be checked for reasonableness. Subsection 4.3.C of AACE International Recommended Practice No. 29R-03 on Forensic Schedule Analysis discusses questions to consider regarding whether activities on the as-built critical path are reasonable, including:

- Was the work critical on any schedule updates?

- Was the work perceived to be critical by project personnel contemporaneously as documented in letters, meeting minutes, etc.?

- Was the work qualitatively significant to the overall project outcome based on cost as well as the analyst’s judgment and experience?

- Were there resource restraints not evident in the logic?

- Was the work performed piecemeal or from start to finish without interruption?

- Did the work drive other subsequent apparently critical work?

Finally, if a delay to any as-built activity would have delayed the overall project completion date by that same duration, it is reasonable to conclude that the activity was on the as-built critical path.

8. CONCLUSION

As-built critical path calculation involves: 1) verifying the accuracy of the as-built schedule dates, 2) converting as-planned logic to as‑built logic, 3) creating an As-Built Calculation Schedule for each schedule analysis window, 4) destatusing the actual dates and replacing them with actual activity and lag durations and percent complete values, 5) determining the driving predecessor relationships, 6) calculating the as-built critical and near-critical paths, and 7) reviewing the calculated as-built critical path for reasonableness. The above steps are performed prior to any delay analysis and should be performed in a consistent manner. Any assumptions should be documented to minimize subjectivity. The schedule analyst’s judgment and experience, however, will always be necessary to ensure the reasonableness of the as-built critical path calculations.

REFERENCES

1 Hoshino, Kenji P., 2002 Slide presentation (No paper published), Catching the Elusive As‑Built Critical Path, 2002 AACE International Transactions, AACE International, Morgantown, WV.

2 Winter, Ronald M., 2004, PS.02—Determining the Actual Critical Path, 2004 AACE International Transactions, AACE International, Morgantown, WV.

3 Nagata PSP, Mark F., 2010, CDR.02—Which Critical Path: As-Planned, Contemporaneous, or As-Built?, 2010 AACE International Transactions, AACE International, Morgantown, WV.

4 Livengood, CFCC, John C. and Jeffery L. Ottesen, PE CFCC PSP, 2010, CDR.06—The As‑Built Critical Path—Quest or Discovery?, 2010 AACE International Transactions, AACE International, Morgantown, WV.

5 AACE International Recommended Practice No. 29R-03, Forensic Schedule Analysis, April 25, 2011 Revision, AACE International, Morgantown, WV.

About the Author

Andrew Avalon, P.E., PSP, is Chairman of Long International, Inc. and has over 35 years of engineering, construction management, project management, and claims consulting experience. He is an expert in the preparation and evaluation of construction claims, insurance claims, schedule delay analysis, entitlement analysis, arbitration/litigation support and dispute resolution. He has prepared more than thirty CPM schedule delay analyses, written expert witness reports, and testified in deposition, mediation, and arbitration. In addition, Mr. Avalon has published numerous articles on the subjects of CPM schedule delay analysis and entitlement issues affecting construction claims and is a contributor to AACE® International’s Recommended Practice No. 29R‑03 for Forensic Schedule Analysis. Mr. Avalon has U.S. and international experience in petrochemical, oil refining, commercial, educational, medical, correctional facility, transportation, dam, wharf, wastewater treatment, and coal and nuclear power projects. Mr. Avalon earned both a B.S., Mechanical Engineering, and a B.A., English, from Stanford University. Mr. Avalon is based in Orlando, Florida and can be contacted at aavalon@long-intl.com and (407) 445‑0825.

Originally published by AACE International as Technical Paper PS.1691 in the 2014 AACE International Transactions.

Reprinted with the permission of AACE International, 1265 Suncrest Towne Centre Dr., Morgantown, WV 26505 U.S.A.

Telephone: +1 (304) 296-8444 | Facsimile: +1 (304) 291-5728 | web.aacei.org | Email: info@aacei.org

Copyright © 2014 by AACE International; all rights reserved.

ADDITIONAL RESOURCES

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE