The Collapsed As‑Built Windows Schedule Analysis Method

This paper addresses the usage of the Collapsed As-Built Windows protocol and the advantages and disadvantages of the methodology.

ABSTRACT

The Collapsed As‑Built Windows Schedule Delay Analysis (AACE® International Recommended Practice 29R‑03, Method Implementation Protocol 3.9) is a modeled, subtractive, multiple‑base method. It is a retrospective CPM schedule analysis which is typically used to prove entitlement for compensable delay and assess concurrency of delay within a window of time. The analysis simulates the as‑built conditions within a schedule window and then delays are removed from the CPM model. If the forecasted project finish date “collapses” but‑for or absent compensable delays, then entitlement for compensable time‑related costs can be demonstrated. This article addresses the usage of the Collapsed As‑Built Windows protocol and the advantages and disadvantages of the methodology.

1. INTRODUCTION

It is common that an unanticipated event or issue may cause delay and extend the overall completion of a project. It is also common that project stakeholders may dispute the responsibility for a project issue that caused delay and extended the overall completion of a project. A project issue can become contested, cause multiple delays, affect several areas of a project, occur at different points in time, and become intertwined with non‑contested issues. To achieve an equitable resolution of a contested project issue that caused delay, it is imperative for a schedule impact analyst to answer the following basic questions:

- Who caused the delay?

- Why did the delay occur?

- What impact did the delay cause?

- Where did the delay occur?

- When did the delay occur?

On large and complex projects, the process of evaluating delay issues is further complicated when the schedule file is comprised of numerous process areas/units, thousands of activities with activity groups spanning many months or years, and multiple critical and near‑critical paths. One retrospective forensic schedule analysis that can be used to evaluate concurrency and quantify compensable delay is the Collapsed As‑Built delay analysis method applied on a windows basis (AACE® International Recommended Practice 29R‑03, MIP 3.9).

2. THE COLLAPSED AS‑BUILT WINDOWS ANALYSIS DEFINED

The Collapsed As‑Built Windows Delay Analysis is generally defined as a retrospective analysis method that models the overall completion date of a project schedule absent identified owner delays based on a defined as‑built portion of a schedule. If the overall completion date is calculated at an earlier date absent identified owner delays, then a contractor may be entitled to compensable time and potential reimbursable delay costs.

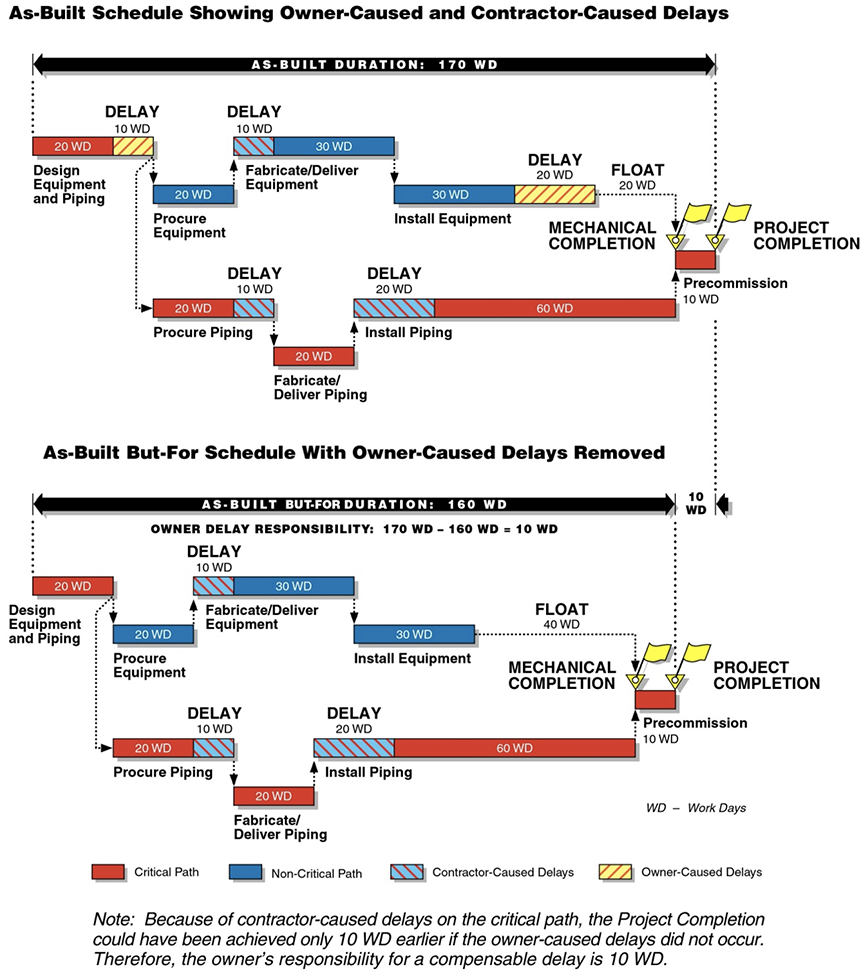

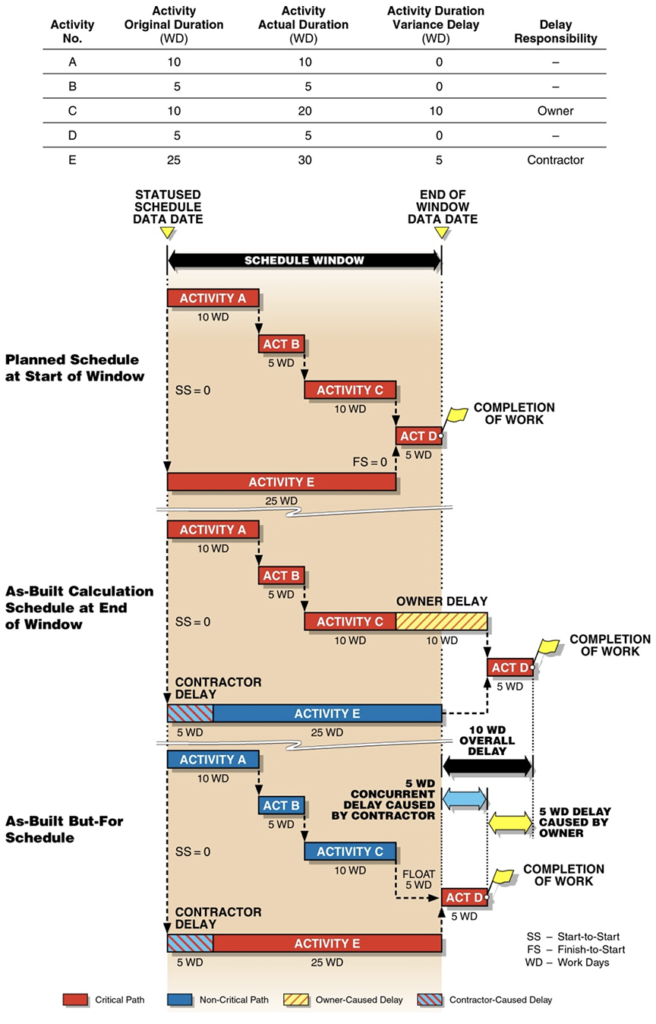

Because the analysis is based on windows of time, it quantifies the cumulative impact of compensable delays based on what actually happened during various time periods throughout the duration of a project. The analysis periods are typically based on a contractor’s monthly contemporaneous schedule updates. The schedule impact analysis periods may also represent several combined consecutive schedule updates based on key impacting project events or significant changes to the project’s critical path. The Collapsed As‑Built Windows Analysis is conceptually depicted in Figure 1 below and includes the following process:

First, a model of the as‑built schedule, which is called the As‑Built Calculation Schedule, is developed with schedule logic and activity durations that calculate the same start and finish dates as the as‑built dates in the as‑built schedule. However, these dates are determined by the as‑built logic and actual activity durations rather than the locked‑in actual start and finish dates of the as‑built schedule. The owner‑caused and contractor‑caused delays are then identified in the As‑Built Calculation Schedule. The owner‑caused delays are removed from the As‑Built Calculation Schedule, leaving the contractor‑caused delays and other excusable but noncompensable delays in the As‑Built Calculation Schedule. In this example, the calculated project completion date collapses to an earlier completion date by only 10‑work days because other delays that were caused by the contractor would prevent the project from being completed any earlier than a reduced duration of 10‑work days. Therefore, the owner’s responsibility for compensable delay is 10‑work days, although the sum of the periods of actual delay was longer, because of delays that were in the as‑built schedule for which the owner is not responsible.

Figure 1

Collapsed As‑Built Window Analysis Example

Unlike the Time Impact Analysis (i.e., AACE® International RP 29R‑03 MIP 3.7), which is calculated at the beginning of a window or schedule analysis period using impacts to the forecasted critical path as a measure of delay, the Collapsed As‑Built Windows Analysis simulates the as‑built conditions for those schedule activities that actually started or finished within the analysis window. Further, the analysis identifies the specific activities on the actual critical path through each analysis window.

This is an important distinction between the Time Impact Analysis and the Collapsed As‑Built Windows Analysis. It is not uncommon for the critical path at the start of the window to change and become different compared to the critical path at the end of the window. Changes to the critical path can be caused by issues such as approved owner changes, disputed changes, weather, force majeure events, or concurrent contractor performance problems.

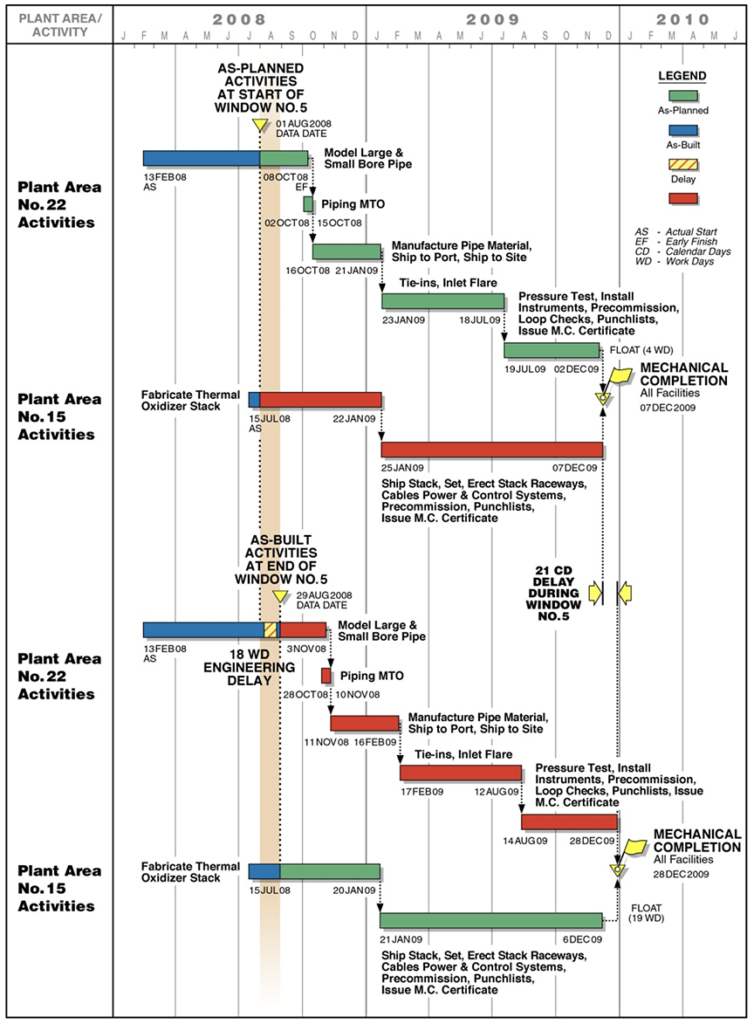

If the emphasis of a schedule delay analysis is to only examine and model impacts to the critical path at the start of a window, then it is possible that owner‑caused or contractor‑caused delays to the actual critical path through the analysis window may be overlooked. Further, the basis for granting compensable time without examining what actually occurred during the analysis window may be in question. To illustrate, Figure 2 below compares the critical path at the start of an analysis window compared to the critical path at the end of the window from a sample oil and gas project schedule.

Figure 2

The Critical Path at the Start of an Analysis Window May Be

Different Compared to the Critical Path at the End of the Window

In Figure 2, work activities associated with Plant Area No. 15 were identified as the critical path at the start of analysis Window No. 5 while Plant Area No. 22 work activities were identified as the near‑critical path. When compared to the end of analysis Window No. 5, Plant Area No. 22 work activities became critical path due to an 18‑day engineering delay to the design development of the Model Large & Small Bore Pipe work that occurred during the analysis period. Plant Area No. 15 work activities have available float compared to the critical path work activities in Plant Area No. 22 at the end of Window No. 5.

2.1 WHY THE COLLAPSED AS‑BUILT WINDOWS ANALYSIS METHODOLOGY IS APPROPRIATE

The Collapsed As‑Built schedule delay analysis is an industry recognized methodology utilized by both owners or contractors to quantify and allocate compensable delay.2, 3, 4, 5 An industry-recognized commentator stated that:6

The as‑built but‑for method is popular with both developers and contractors because, unlike the as‑planned impacted method, it is based on consideration of the actual build times and can be used for determining not only the period of excusable delay, but also the period over which loss and expense may have been suffered.

Furthermore, the analysis provides the analyst with the ability to reinforce the causal link between an owner delay relative to the as‑built critical path in the actual time period when the delay occurred:7

The effect of the causal event on the key dates and completion date is then the difference between the date calculated before the event was subtracted, and that calculated after the event was subtracted.

Hence, the primary benefit of this analysis is to evaluate what actually happened during a period of time when compensable delay claims are alleged:8

[O]ne of the arguments frequently encountered is the issue of hindsight pricing of delays, as opposed to current or contemporaneous pricing of delays. We might describe this as the need to answer a requirement or argument for the use of the but for test in the evaluation process. This should be satisfied if delays are evaluated update by update both at the beginning and end of updates, not only to identify where the critical path is located at the inception of the period but also to locate the critical path during the period and to assure that the critical path was not overtaken by other delays (or concurrent with other critical path delays) during the month in question.

Some in the industry believe that, if a contractor can prove entitlement for a time extension, a contractor should automatically receive compensable time.9, 10 Depending on the contract terms and jurisdiction, the contractor may not be entitled to compensation for an excusable delay if the contractor is also responsible for concurrent noncompensable delays. For instance, if the project record can demonstrate that a contractor was extended both by an owner‑caused delay and a concurrent contractor‑caused delay, an owner should only have to pay for its contribution to critical path delays and not for a contractor’s contribution to critical path delays. The Collapsed As‑Built Windows Analysis quantifies the compensable delay and addresses the issue of actual concurrent delay within an analysis window, which the Time Impact Analysis may not analyze properly. The topic of a contractor’s inability to recover compensable delay damages when concurrent contractor delay exists is discussed and underscored in Section 4.1.C of AACE® International Recommended Practice No. 29R‑03 which states the following:11

Note that the terms, compensable, excusable and non‑excusable, in current industry usage, are from the viewpoint of the contractor. That is, a delay that is deemed compensable is compensable to the contractor, but non‑excusable to the owner. Conversely, a non‑excusable delay is a compensable delay to the owner since it results in the collection of liquidated damages.

A neutral perspective on the usage of the terms often aids understanding of the parity and symmetry of the concepts. Thus entitlement to compensability, whether it applies to the contractor or the owner, requires that the party seeking compensation show a lack of concurrency if concurrency is alleged by the other party. But for entitlement to excusability without compensation, whether it applies to the contractor or the owner, it only requires that the party seeking excusability show that a delay by the other party impacted the critical path.

Based on this symmetry, contractor entitlement to a time extension does not automatically entitle the contractor to delay compensation. The contractor would first have to show that an owner delay impacted the critical path, and then if the owner defends alleging concurrent delay, the contractor would have to show the absence of concurrent delays caused by a contractor delay or a force majeure delay in order to be entitled to compensation. [Emphasis added.]

A contractor delay concurrent with many owner delays would negate the contractor’s entitlement to delay compensation. Similarly, one owner delay concurrent with many contractor delays would negate the owner’s entitlement to delay compensation, including liquidated/stipulated damages. While, in such extreme cases the rule seems draconian, it is a symmetrical rule that applies to both the owner and the contractor and hence ultimately equitable. [Emphasis added.]

The Collapsed As‑Built Windows Analysis is a methodology that quantifies the net effect but‑for owner‑caused delays that may or may not affect the simulated actual critical path through an analysis window.

2.2 CRITICISMS OF THE COLLAPSED AS‑BUILT WINDOWS ANALYSIS

Many schedule impact analysis practitioners have voiced concerns and have reservations regarding the application of the Collapsed As‑Built Windows Analysis methodology. The authors agree that the Collapsed As‑Built Windows Analysis methodology is a retrospectivity analysis and it may not be appropriate depending on the facts of delay, contract requirements, and purpose of the delay analysis (e.g., determination of a time extension). Further, the application of the analysis has advantages and disadvantages as discuss later in this article. However, in the following paragraphs, the authors will respond to the top six (6) most‑voiced concerns regarding the usage of the Collapsed As‑Built Windows Analysis methodology:

- As‑Built Logic Subjectivity – During the development of the As‑Built Calculation schedule, many have criticized the potential subjectivity by the analyst when adjusting the activity logic and lags to represent the as‑built conditions during the analysis window. To counter this criticism, a good practice is to establish well‑defined as‑built logic guidelines designed to alleviate alleged subjectivity and increase analysis objectivity. For each analysis window, these guidelines should be applied consistently and any potential deviations from the guidelines should be documented with detailed notes and explanations.

- Chronological and Cumulative Delay Evaluation Issues – Some have criticized that the application of the Collapsed As‑Built Windows Analysis does not properly evaluate delay events prospectively, chronologically, and cumulatively. If the analysis uses only one window for the entire as‑built duration, then these criticisms may have some validity. However, this is not the case when using the Collapsed As‑Built Windows Analysis RP 29R‑03, MIP 3.9, which is applied using two or more analysis windows. Based on the actual start or finish of one or multiple delay events that occurred within the analysis window, delay events are analyzed using the as‑built critical path that could change from update‑to‑update. Critical path delay is identified and the amount of delay is allocated to the responsible party. The evaluated delay event for each analysis window is then summed to determine the cumulative impact from delays relative to concurrency and compensable time.

- Does Not Consider Time Extensions Contemporaneously – A common criticism is that an after‑the‑fact approach, such as the Collapsed As‑Built Windows Analysis, does not consider contract time extensions contemporaneously. Although this criticism may have validity in some cases, the determination of a contractor’s entitlement for a time extension contemporaneously is not typical purpose for using the Collapsed As‑Built Windows Analysis. The objective of the Collapsed As‑Built Windows Analysis is to identify, quantify, and allocated compensable delay, including the potential offset from concurrent contractor‑caused delay based on what actually happened during an analysis window.

- Contractor Pacing Arguments – Contractors will often assert that certain delays in the as‑built schedule were “pacing delays.” A contractor pacing delay is generally defined as deliberate slow down or delay by a contractor to keep pace with a driving owner‑caused delay. Some have argued that these pacing delays would not have happened due to owner‑caused delay, but many commentators do not identify the most appropriate schedule delay methodology to identify and quantify potential contractor pacing. If the contractor can provide documented support of a pacing argument, the Collapsed As‑Built Windows Analysis is an excellent analytical tool to evaluate potential pacing arguments, and for that matter, concurrent delay issues.

- Continuity Between As‑Built Start and Finish Dates – Another noted concern is the possibility that the actual work between as‑built start and finish dates may not be continuous. The Collapsed As‑Built Windows Analysis compares planned/forecasted durations and lags at the start of the analysis window to the corresponding as‑built durations and lags at the end of the analysis window. Any variances are then examined to determine if any delay has occurred. Activity variances are also examined for evidence of pacing delay or contractor performance problems, for example, due to insufficient labor resources. Delays should be allocated to the owner or contractor based on the factual evidence. Thus, an analysis of the project records will allow the analyst to explain the variance even though the actual work for an activity may not be continuous.

- As‑Built Date Concerns – Some have expressed concern regarding the accuracy of activity as‑built dates. As‑built date verification is an important step in the implementation of the Collapsed As‑Built But‑For Windows Analysis. As with any type of schedule delay analysis, the accuracy of quantifying activity delay is limited to the available information that can be used to verify as‑built dates. Therefore, an analyst should give consideration to the guidelines established in AACE® International’s Recommend Practice 29R‑03 of 25 April 2011, Section 2.2, pages 22 to 28, regarding source validation of the as‑built schedule.

2.3 SUMMARY OF STEPS TO CONSIDER FOR DEVELOPING A COLLAPSED AS‑BUILT WINDOWS ANALYSIS

When developing and applying the Collapsed As‑Built Windows Analysis methodology, several basic steps should be considered. These steps are vital to ensure that the schedule model is accurate, reasonable, free of obvious schedule problems, and allows the analyst to quantify and allocate responsibility for compensable delays. The recommended basic steps include the following:12

- Step 1 – Identification of Schedule Windows

- Step 2 – Correction of the Schedules and Verification of Actual Dates

- Step 3 – Development of a Reasonable As‑Planned Schedule for the Start of Each Schedule Window

- Step 4 – Development of As‑Built Calculation Schedules for Each Schedule Window

- Step 5 – Preparation of Duration and Lag Variance Tables

- Step 6 – Identification of Delays and Allocation of Delay Responsibility

- Step 7 – Schedule Calculations to Determine Delay Liability

A more detailed discussion for each of these steps is explained in “The New Modeled, Subtractive, Multiple Base MIP 3.9 Forensic Schedule Analysis Protocol” included in AACE® International’s 2009 Transactions.12

2.4 THE KEY COMPONENT TO THE WINDOWS DELAY ANALYSIS – THE AS‑BUILT CALCULATION SCHEDULE

The underlying premise to the Collapsed As‑Built Windows Analysis is to quantify potential compensable delay within each analysis window but‑for owner‑caused delay issues. This is accomplished by preparing an As‑Built Calculation Schedule that simulates as‑built conditions (i.e., actual start and finish dates, actual durations, and actual lag values) for work performed within the analysis window between schedule updates. The As‑Built Calculation schedule is typically based on a copy of the contemporaneous schedule file at the end of the analysis window.

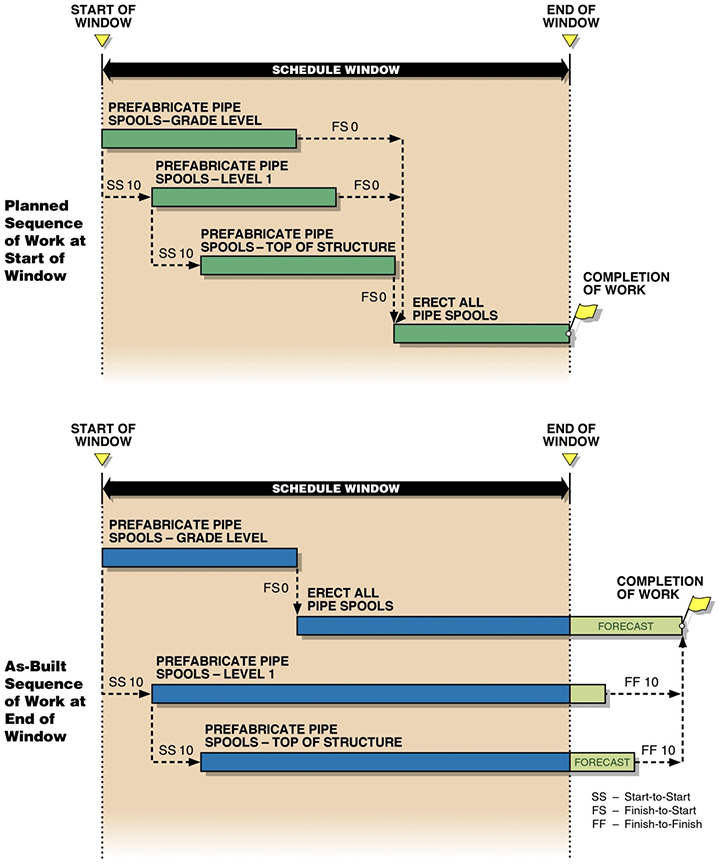

The As‑Built Calculation Schedule converts and replicates as‑built data into matching planned or forecasted data based on a data date at the start of the analysis window. The As‑Built Calculation Schedule also replicates the forecasted dates for those activities outside the analysis window. This allows the analyst to use trace logic to identify the driving critical and near‑critical paths from the latest finish activity back through the analysis window. In this manner, the delay on the as‑built critical path can be determined rather than basing delay on the as‑planned critical path which could be different. This is illustrated in Figure 3 below showing a different as‑built condition at the end of the analysis window compared to the planned condition as the start of the analysis window.

Figure 3

As‑Built Conditions May Be Different than the Plan at the Start of the Analysis Window

Once the As‑Built Calculation Schedule is prepared, it is then recalculated absent owner‑caused delays to determine the “but‑for” completion date.

2.5 QUANTIFICATION OF DELAY

In Figure 3 above, the analyst can then compare and quantify what actually happened during the analysis window to the plan at the start of the analysis window including a change in sequence. If a variance is identified and quantified within the analysis window, the analyst can model the effect on the project completion date by removing known owner‑caused delay affecting specific work activities. This is further illustrated in the following example that quantifies duration variances within the analysis window, identifies who is responsible for the variance, and then removes owner‑caused delay:1

In this case, a 10‑work day owner‑caused delay and a 5‑work day contractor‑caused delay were identified in the window by comparing the original and actual activity durations during the window. An As‑Built Calculation Schedule was prepared to model the owner‑caused and contractor‑caused delays. If the 10‑work day owner‑caused delay is then removed from the schedule network, the Completion of Work milestone collapses to a date which is only 5 work days beyond the original Completion of Work date because the 5‑work day contractor‑caused delay becomes the remaining driving critical path delay. Therefore, the contractor is only entitled to a 5‑work day compensable delay. (see Figure 4 below).

Figure 4

Example of an Owner‑Caused Delay Quantified by a Duration Variance Calculation

2.6 INTERPRETING THE RESULTS FROM THE COLLAPSED AS‑BUILT WINDOWS ANALYSIS

Removing owner‑caused delays from the As‑Built Calculation Schedule may or may not result in an earlier overall completion date. If the overall completion date in the As‑Built Calculation Schedule collapses to an earlier date but‑for owner‑caused delays, then the contractor may have entitlement to some compensable time.

As shown in Figure 4 above, the overall completion slipped a total of 10 work days when comparing the planned completion date at the start of the analysis window to the forecasted completion date at the end of the analysis window. However, in this situation, the owner was responsible for 5 work days of compensable delay to the contractor although the overall project completion slipped a total of 10 work days due to 5 work days on contractor‑caused delay found on the collapsed as‑built critical path. The examples below identify three potential results based on partial or no collapse of the As‑Built Calculation Schedule:1

If the As‑Built Calculation Schedule does not collapse at all, or only collapses partially (i.e., not to the original projected completion date at the start of the window), the owner‑caused delays removed were either:

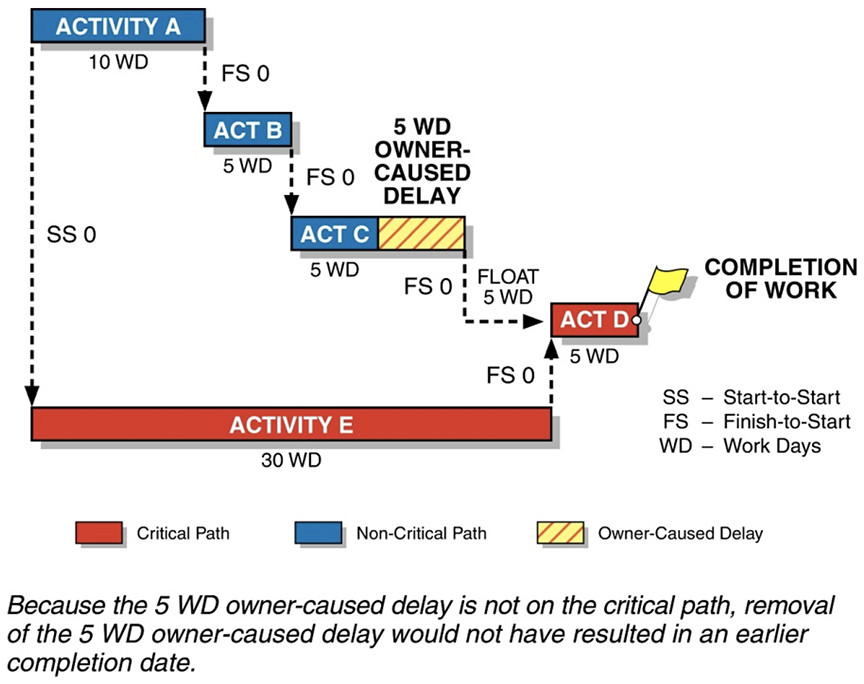

a. not on the critical path and, therefore, the owner‑caused delay would not have affected the completion date(s), as shown by Figure 5. In this case, the 5 work day owner‑caused delay affected Activity C, which still had 5 work days of available float after the delay occurred because Activity E and Activity D were the actual critical path to the Completion of Work; or

Figure 5

Owner‑Caused Delays Were Not on the Critical Path

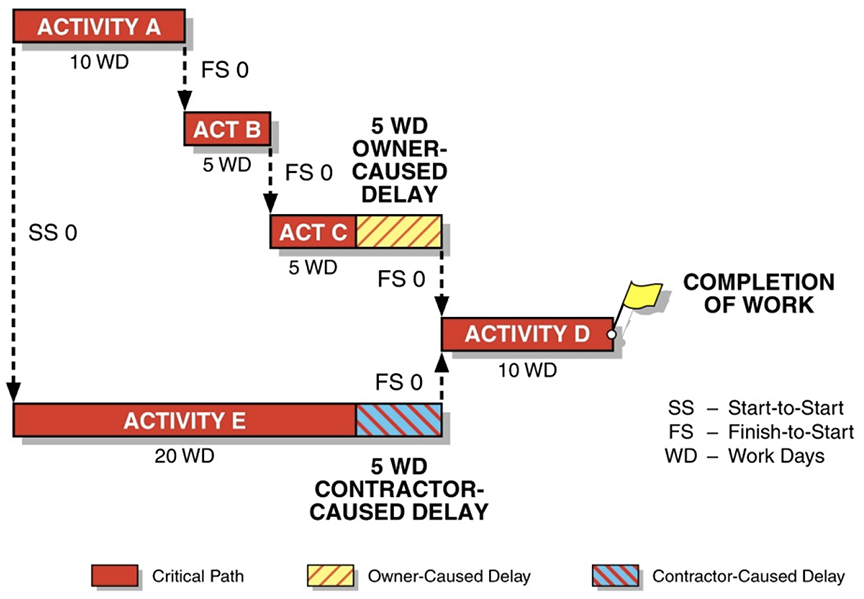

b. concurrent with contractor‑caused delays or other noncompensable but excusable delays that were also on the as‑built critical path which prevented the schedule completion date from collapsing to the original projected completion date at the start of the window, as shown by Figure 6. In this example, the 5‑work day owner‑caused delay and the 5‑work day contractor‑caused delay affected two parallel activity paths, were independent delays, and both delays would have extended the completion of the project. Therefore, because of the contractor‑caused delay was fully concurrent with the owner‑caused delay, the completion date(s) would not have occurred any earlier if the owner‑caused delays had not occurred; or

Figure 6

Owner‑Caused Delays Were Fully Concurrent with Contractor‑Caused Delays

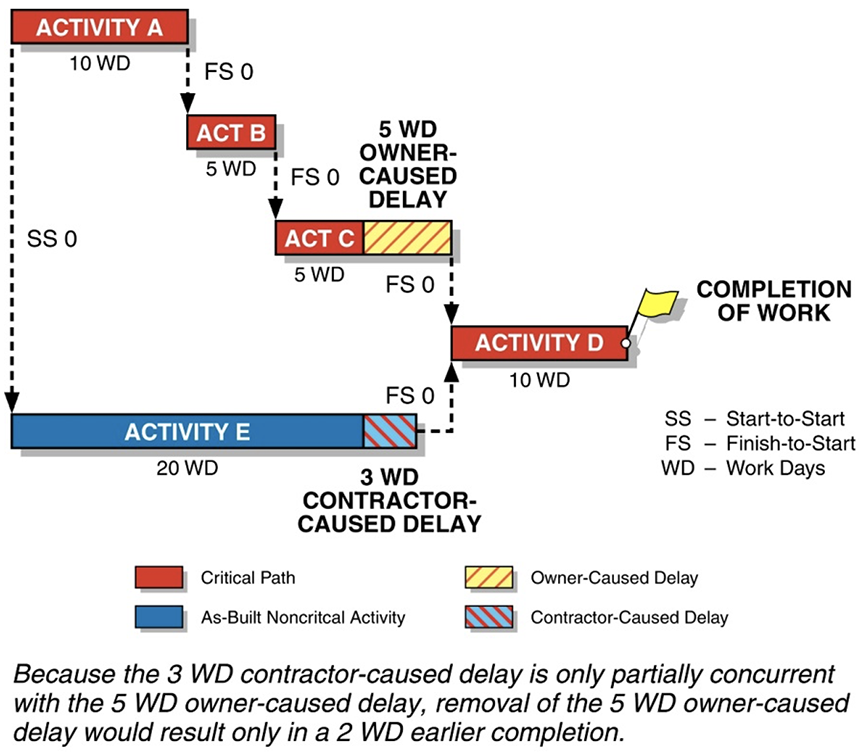

c. concurrent in part, but not for the entire owner‑caused delay period, with contractor‑caused delays or other noncompensable but excusable delays that were also on the as‑built critical path which prevented the scheduled Completion of Work date from totally collapsing to the original projected Completion of Work date at the start of the window, as shown by Figure 7. In this example, a 5‑work day owner‑caused delay occurred on a parallel activity path (Activity A, B and C) to Activity E, which experienced a 3‑work day contractor‑caused delay. Removal of the 5‑work day owner‑caused delay would only allow the schedule to collapse by 2 work days because of the parallel contractor‑caused delay. Therefore, because of the contractor-caused delay being partially concurrent with the owner‑caused delay, the Completion of Work date(s) would have occurred earlier if the owner‑caused delay had not occurred only to the extent that the owner‑caused delays were not concurrent with the contractor‑caused delays.

Figure 7

Owner‑Caused Delays Were Partially Concurrent with Contractor‑Caused Delays

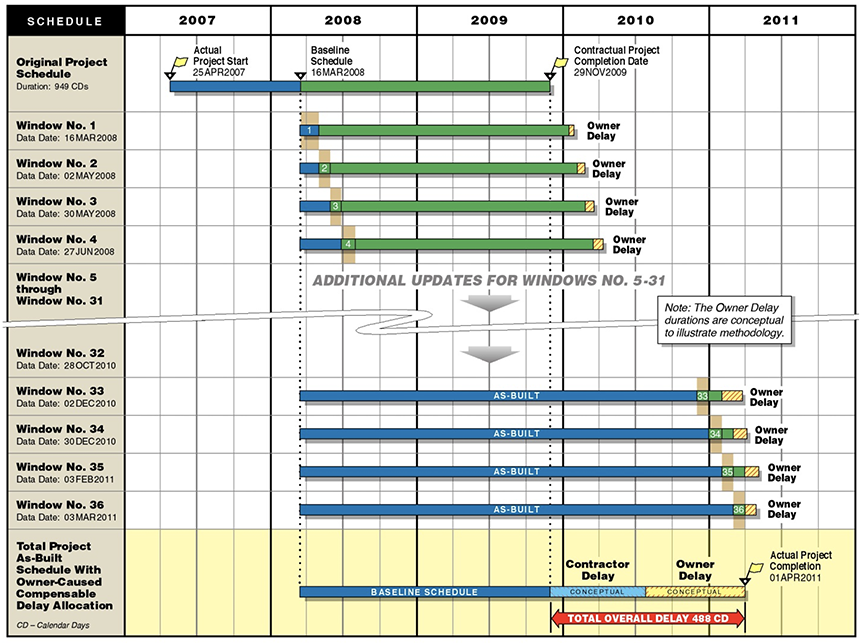

After removing owner‑caused from the individual As‑Built Calculation Schedule prepared for each analysis window, the analyst then totals the number of days of collapse, if any, for each period. The total number of collapsed days would represent the number of compensable delay days that the contractor may be entitled to receive. Figure 8 provides a summary in graphical form of the total number of compensable delay days.

Figure 8

Net Overall Compensable Delay for All Windows (Conceptual)

2.7 THE ADVANTAGES AND DISADVANTAGES TO THE COLLAPSED AS‑BUILT WINDOWS SCHEDULE ANALYSIS

The Collapsed As‑Built Windows Analysis is primarily used to calculate compensable delay by identifying, quantifying, and allocating responsibility for compensable and noncompensable delays and assessing concurrency. The Collapsed As‑Built Windows Analysis has the following investigative advantages which can support credible opinions regarding compensable and noncompensable delay:

- As‑Built methods are generally favored by courts because they rely on factual records and are based on what actually happened within the analysis window.

- It relies upon the as‑built critical path at the end of the window instead of the planned critical at the start of the window.

- It quantifies the relative impact of concurrent owner and contractor‑caused delays.

- It allocates and calculates compensable delay that may affect critical and near‑critical paths.

- It allows for the assessment and consideration of “Pacing” delays.

Conversely, the Collapsed As‑Built Windows schedule analysis may also have potential disadvantages that an analyst should consider, including the following:

- As‑built date verification can be time consuming and costly.

- The analysis could potentially be biased to choose a critical path that helps gain the most delay compensation. However, similar biases may also exist in other schedule impact analysis methods.

- The analysis may incorrectly assume that the as‑built condition in the analysis window would not change if the delay or delays did not occur.

- If the analysis is based on inaccurate schedules to determine delay responsibility and liability, then the results from the Collapsed As‑Built Windows Analysis may produce unreliable and incorrect results and opinions.

- Determination of the as‑built critical path may be subjective if there are several critical paths to choose from.

- The Collapsed As‑Built Windows Analysis is not the best analytical tool for determining an appropriate time extension for the cumulative impact from excusable delays or a basis for apportioning acceleration and disruption costs.

The selection and usage of the Collapsed As‑Built Windows Analysis is dependent on several factors. As discussed in detail within AACE® International’s Recommend Practice 29R‑03 of 25 April 2011, Section 5, pages 125 to 131, when selecting a schedule analysis method, the analyst should consider several factors such as contract requirements, purpose, available data, reliable data, dispute size, budget to perform the analysis, time available, qualifications of the analyst, forum of the dispute, legal requirements, and appropriate usage of the method.

About the Authors

Andrew Avalon, P.E., PSP, is Chairman and CEO of Long International, Inc. and has over 35 years of engineering, construction management, project management, and claims consulting experience. He is an expert in the preparation and evaluation of construction claims, insurance claims, schedule delay analysis, entitlement analysis, arbitration/litigation support and dispute resolution. He has prepared more than thirty CPM schedule delay analyses, written expert witness reports, and testified in deposition, mediation, and arbitration. In addition, Mr. Avalon has published numerous articles on the subjects of CPM schedule delay analysis and entitlement issues affecting construction claims and is a contributor to AACE® International’s Recommended Practice No. 29R-03 for Forensic Schedule Analysis. Mr. Avalon has U.S. and international experience in petrochemical, oil refining, commercial, educational, medical, correctional facility, transportation, dam, wharf, wastewater treatment, and coal and nuclear power projects. Mr. Avalon earned both a B.S., Mechanical Engineering, and a B.A., English, from Stanford University. Mr. Avalon is based in Orlando, Florida and can be contacted at aavalon@long‑intl.com and (407) 445-0825.

Ronald J. Rider, M.B.A., is a Senior Principal with Long International and has over 30 years of experience in construction project management and contract dispute resolution. Mr. Rider has performed CPM schedule development, project cost control, cost and labor hour variance modeling, impact identification and causation, change order pricing and resolution, retrospective schedule delay, time extension and acceleration analyses, concurrent delay assessments and damages quantification. Mr. Rider’s experience includes petrochemical, oil refinery, power, commercial, industrial, road/highway, transit, hospital/medical, airport and casino projects. He holds a B.S. degree in construction management from Colorado State University and an M.B.A. degree from the University of Colorado. Mr. Rider is based in the Denver, Colorado area and can be contacted at rrider@long‑intl.com and (303) 346-5836.

Acknowledgements

The authors wish to thank Richard J. Long, P.E., P.Eng., Founder of Long International, for his contributions to this article.

Richard J. Long, P.E., P.Eng., is Founder of Long International, Inc. Mr. Long has over 50 years of U.S. and international engineering, construction, and management consulting experience involving construction contract disputes analysis and resolution, arbitration and litigation support and expert testimony, project management, engineering and construction management, cost and schedule control, and process engineering. As an internationally recognized expert in the analysis and resolution of complex construction disputes for over 35 years, Mr. Long has served as the lead expert on over 300 projects having claims ranging in size from US$100,000 to over US$2 billion. He has presented and published numerous articles on the subjects of claims analysis, entitlement issues, CPM schedule and damages analyses, and claims prevention. Mr. Long earned a B.S. in Chemical Engineering from the University of Pittsburgh in 1970 and an M.S. in Chemical and Petroleum Refining Engineering from the Colorado School of Mines in 1974. Mr. Long is based in Littleton, Colorado and can be contacted at rlong@long-intl.com and (303) 972-2443.

1 Long, P.E., P.Eng., Richard J., “As‑Built But‑For Schedule Analysis,” Long International, Inc., Littleton, CO, 2017.

2 Wickwire, Jon M., Driscoll, Thomas J., Hurlbut, Stephen B., and Hillman, Scott B., 2nd Edition, Construction Scheduling: Preparation, Liability and Claims, Aspen Law & Business, New York, NY, 2003, Section 9.08[I], pp. 372 to 374 and Section 9.06[B], pp. 272 to 273.

3 The Society of Construction Law Delay and Disruption Protocol, 2002, Oxford, UK, Section 4.7, p. 47.

4 Pickavance, Keith, Delay and Disruption in Construction Contracts, 3rd Edition, T&F Informa (UK) Ltd., London, UK, 2005, p. 564, paragraph 14.292.

5 Keane, P.J. and Caletka, A.F., Delay Analysis in Construction Contracts, Wiley‑Blackwell, 2008, Section 4.2.4, pp. 140 to 150.

6 Pickavance, Keith, Delay and Disruption in Construction Contracts, 3rd Edition, T&F Informa (UK) Ltd., London, UK, 2005, p. 566, paragraph 14.306.

7 Pickavance, Keith, Delay and Disruption in Construction Contracts, 3rd Edition, T&F Informa (UK) Ltd., London, UK, 2005, p. 564, paragraph 14.293.

8 Wickwire, Jon M., Driscoll, Thomas J., Hurlbut, Stephen B., and Hillman, Scott B., 2nd Edition, Construction Scheduling: Preparation, Liability and Claims, Aspen Law & Business, New York, NY, 2003, Section 9.10, pp. 413 to 414.

9 Wickwire, Jon M., Driscoll, Thomas J., Hurlbut, Stephen B., and Hillman, Scott B., 2nd Edition, Construction Scheduling: Preparation, Liability and Claims, Aspen Law & Business, New York, NY, 2003, Section 9.08[G]1, pp. 350 to 355.

10 The Society of Construction Law Delay and Disruption Protocol, 2002, Oxford, UK, Paragraph 1.6.3, p. 18.

11 AACE® International Recommended Practice No. 29R‑03, Forensic Schedule Analysis, AACE® International, Morgantown, WV, April 25, 2011 Revision, Section 4.1.C, pp. 100 to 101.

12 Avalon, P.E., PSP, Andrew and Rider, MBA, Ronald J., CDR.06 – The New Modeled, Subtractive, Multiple Base MIP 3.9 Forensic Schedule Analysis Protocol, 2009, AACE® International Transactions, AACE® International, Morgantown, WV.

Originally published by AACE International as CDR.2708 in the 2017 AACE International Transactions.

Reprinted with the permission of AACE International, 1265 Suncrest Towne Centre Dr., Morgantown, WV 26505 USA

Telephone: +1 (304) 296-8444 | Facsimile: +1 (304) 291-5728 | web.aacei.org | info@aacei.org

Copyright © 2017 by AACE International; all rights reserved.

ADDITIONAL RESOURCES

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE