November 6, 2023

Is the Critical Path Valid?

This blog post addresses challenges to determining the validity of the critical path. This is the third post in a five-part series that discusses critical path validity. The first post discusses the purpose of time management on construction projects, and the second post concerns defining the critical path. The fourth post addresses critical path schedule quality checks, and the fifth discusses steps to consider for identifying the critical path.

Regardless of the size and complexity of a project schedule, it is important to verify the validity of the activities that constitute the critical and near-critical paths. The following two underlying questions need to be explored:

- What is the critical path of the project?

- Is the critical path reasonable?

The answers to these two questions may not be easy to determine. First, on large and complex EPC projects spanning several years, identifying, summarizing, and evaluating the critical and near-critical paths can be cumbersome, especially when multiple activity calendars are used that create differing total float or slack values. It is not unusual for large EPC projects to contain a mixture of process areas represented by tens of thousands of scheduled activities. The sheer magnitude of the schedule data makes identifying the critical and near-critical paths difficult. For example, each work area can become its own individual subproject that has its own specific driving critical path. Each work area can include elements of engineering, procurement, fabrication, delivery, transportation, installation, and commissioning and startup.

Second, the critical path is likely to change or shift multiple times because the Critical Path Method (CPM) model is dynamic. It allows for critical path activities shown in an initial baseline schedule to change in subsequent schedule updates during a project’s execution based on progress achieved at a given point in time. It is not unusual for near-critical path activities to be delayed beyond available float days or slack time for a given update, thus creating a new critical path of activities driving project completion in subsequent updates. Therefore, to complete a project in time, it is crucial to correctly identify and actively manage critical path and near-critical path work activities throughout project performance.

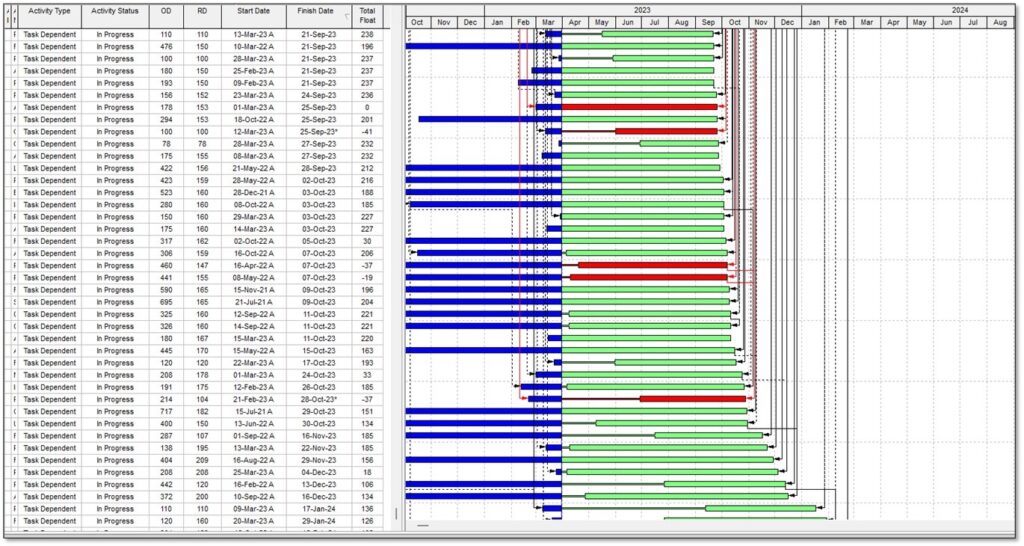

Third, CPM scheduling programs have limitations on how the schedule data output is presented. Many standard output reporting features from the well-known CPM scheduling programs do not provide the user with clear and easy-to-follow instructions that depict the critical path or near-critical paths. Often, the critical path workflow and logic links become muddled. Graphical representations can resemble a jumbled mass of schedule data. Figure 1 is a screen shot of a sample bar chart that includes critical and near-critical path activities sorted by early start dates.

Figure 1

Critical and Near-Critical Path Activities Sorted by Early Start Dates

As shown in Figure 1, the output can be cluttered, and important critical and near-critical schedule information to be conveyed to project stakeholders may be unclear. The horizontal workflow from the data date, engineering, procurement, fabrication, installation, commissioning, and startup is obscured, and it is difficult to evaluate the relationships among the critical and near-critical paths. Furthermore, the evaluation of the critical and near-critical paths can become more challenging if a multitude of change orders and other impacts are introduced into the project schedule.

As discussed in the next post, deficiencies within the schedule file could raise questions about the reasonableness of forecasted critical or near-critical path dates and float or slack values.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

RECOMMENDED READS

Challenges and Considerations in Identifying and Analyzing the Critical Path

This first post in a series on identifying and analyzing the critical path discusses the purpose of time management on construction projects.

READ

The Critical Path Defined

This post explores various kinds of critical paths. It is the second post in a series on identifying and analyzing the critical path.

READ

Calculating the As-Built Critical Path

This article discusses procedures to ensure that the as-built driving lag values are determined objectively to avoid inconsistent or subjective assessments in calculating the as-built critical path.

READ