November 21, 2022

Post-Combustion Carbon Capture: Technologies, Processes, & More

This is the second post in a six-part series that discusses what carbon capture is, its utilization, and sequestration. The series covers topics including: industry background; market overview and drivers; past, current, and planned carbon capture projects; and overviews of typical carbon capture technologies.

As of February 2022, there are approximately 27 operational carbon capture projects globally, with 13 in the U.S.1 Several more projects are planned or underway, with more than 50 projects planned for the coming years.2 This post discusses several representative examples of post-combustion carbon (CO2) capture company technologies, processes, and projects worldwide.

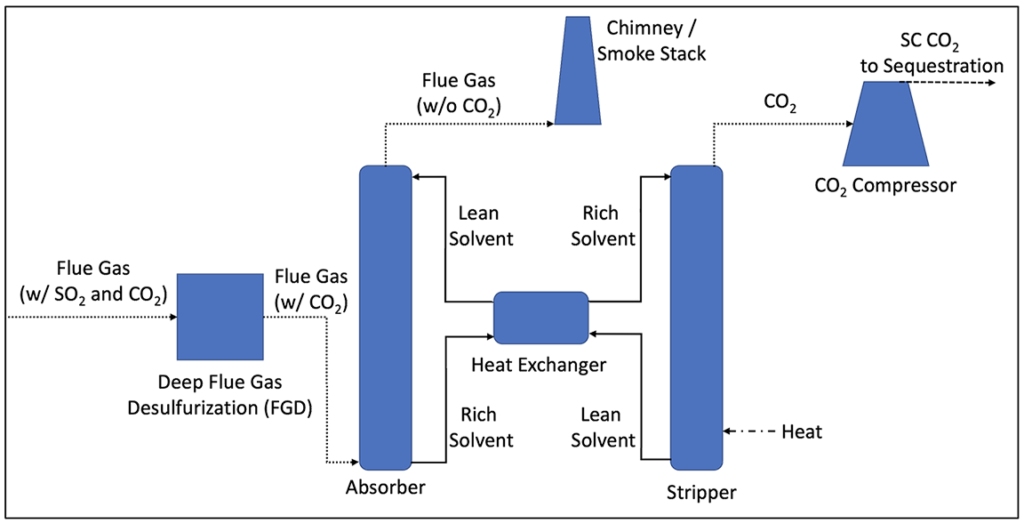

So, what is post-combustion carbon capture? In this process, which is typically employed in the power generation sector, carbon dioxide (CO2) is captured from flue gas streams that result from the combustion of fossil fuels. These flue gases typically contain between 3 and 15% CO2 by volume,3 with flue gases from natural gas-fired power plants exhibiting CO2 concentrations at the lower end of the range and flue gases from coal-fired power plants exhibiting CO2 concentrations at the higher end of the range. The captured CO2 is then typically compressed to its supercritical (SC) state for use in enhanced oil recovery (EOR) operations and/or for long-term sequestration. Figure 1 below shows a simplified carbon capture process flow diagram for a typical post-combustion CCUS system. The technical details of the process will be discussed in a future Long International blog post.

Figure 1: Simplified Post-Combustion CCUS Process Flow Diagram

Representative examples of post-combustion carbon capture company projects are discussed below.

- SaskPower’s Boundary Dam Unit 3, a 160 MW (gross) coal-fired power station near Estevan, Saskatchewan, Canada, became the first power station in the world to successfully use carbon capture technology when its carbon capture retrofit project came online in the fall of 2014.4,5 The carbon capture system was designed by Cansolv Technologies Limited, a subsidiary of Shell Global Solutions, to capture 90% of the plant’s CO2 emissions,6 equal to approximately one million tonnes of CO2 captured per year,7,8 for subsequent use in EOR operations at a nearby oil field. The cost of the carbon capture portion of the retrofit was approximately CAD 800 million.9 SaskPower reported availability issues with the carbon capture system during start-up10 and again more recently in 2021, with the recent issues reportedly due to an issue with the supercritical CO2 compressor motor rather than an issue with the capture technology itself.11

- NRG Energy’s Petra Nova project, a US$1 billion project to retrofit its 650 MW coal-fired W.A. Parish Unit 8 generating station in Texas with carbon capture equipment, came online in 2016.12,13 The carbon capture system, which uses the Kansai Mitsubishi Carbon Dioxide Recovery Process, was designed to capture approximately 1.6 million tons per year of CO2 (approximately 60% more than Boundary Dam) from a 240 MW-equivalent slipstream (approximately one-third of the Unit’s flue gas) for use in EOR.14 Despite reported outages due to the carbon capture facility, the project was generally considered to be successful prior to being shut down in the spring of 2020 due to low oil prices brought on by the pandemic.15 Prior to being taken offline, the system captured nearly four million tons of CO2.16 Figure 2 below contains a picture of the Petra Nova Project, with the carbon capture facility circled in yellow.

- Cleco recently announced that a front-end engineering design (FEED) study, partially funded by US$9 million earmarked in the U.S.’s 2022 Omnibus Appropriations Bill, is currently underway for its Diamond Vault carbon capture project. Diamond Vault, with an estimated project cost of $900 million, will capture up to 95% of the CO2 from the flue gas at Cleco’s 600 MW Madison 3 power generation unit in Louisiana, which burns a mixture of petroleum coke and coal. The captured CO2 will be sequestered in geological formations directly below the Madison 3 unit. The FEED study is expected to be completed in early 2024, with construction expected to begin in 2025 and commercial operation planned to occur no later than 2028.17

Figure 2: NRG’s Petra Nova Project (Texas, U.S.)

- The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) recently announced funding for the completion of FEED studies for natural gas carbon capture systems at power plants:18

- Louisville Gas & Electric’s 700 MW Cane Run 7 in Louisville, Kentucky: DOE will provide US$5.8 million for completion of the FEED study led by the Electric Power Research Institute (EPRI). The proposed project will employ the University of Kentucky’s CO2 capture process to capture approximately 1.7 million tonnes per year with a capture rate greater than 95%.19

- Tampa Electric Co.’s (TECO) 1.2 GW Polk Power Station in Mulberry, Florida: DOE will provide US$5.6 million to conduct a FEED study led by TECO. The proposed project will employ ION Clean Energy Inc.’s CO2 capture process to capture approximately 3.7 million tonnes per year with a capture rate greater than 95%.20

- Alabama Power’s James M. Barry Electric Generating Plant in Bucks, Alabama: FECM awarded US$5.8 million to conduct a FEED study led by GE Gas Power. The proposed project will employ Linde’s Gen 2 carbon capture solution based on BASF OASE blue technology to capture 95% of the CO2 emissions associated with two gas turbines.21

- Calpine’s Deer Park Energy Facility in Deer Park, Texas: DOE is supporting the feed study led by Calpine and Cansolv. The proposed project will be designed to capture at least 95% of the CO2 emissions from flue gas generated by all five turbines at the facility.22

- NTPC Limited, India’s largest power utility, recently announced that it has begun capturing CO2 from the flue gas generated by a 500 MW unit at its coal-fired 4.8 GW Vindhyachal Super Thermal Power Station. The pilot system is designed to capture 20 tonnes of CO2 per day to investigate the conversion of captured CO2 to methanol.23

As detailed above, there are several post-combustion carbon capture projects worldwide that are in operation or planned in the coming years. Subsequent blog posts on this topic will discuss current and planned direct air capture and industrial carbon capture projects and provide overviews of typical carbon capture technologies.

1 Dayen, Dimitry, “Carbon Capture: Early Days of a $1 Trillion Industry?” ClearBridge Investments, February 22, 2022. Accessed September 20, 2022. https://www.clearbridge.com/perspectives/institutional/2022/carbon-capture-early-days-of-a-usd1-trillion-industry.

2 Norton, Kit, “Fueling Carbon Capture In the Oil Industry: Production, Net Zero And ESG,” Investor’s Business Daily, July 29, 2022. Accessed October 2, 2022. https://www.investors.com/news/carbon-capture-oil-industry-production-net-zero-esg/.

3 David, E., V. Stanciu, C. Sandru, A. Armeanu, and V. Niculescu, “Exhaust gas treatment technologies for pollutant emission abatement from fossil fuel power plants,” WIT Transactions on Ecology and the Environment, Vol. 102, 2007. Accessed November 17, 2022. https://www.witpress.com/Secure/elibrary/papers/SDP07/SDP07088FU2.pdf

4 “Boundary Dam Carbon Capture Project,” SaskPower. Accessed October 2, 2022. https://www.saskpower.com/Our-Power-Future/Infrastructure-Projects/Carbon-Capture-and-Storage/Boundary-Dam-Carbon-Capture-Project.

5 “Boundary Dam Fact Sheet: Carbon Dioxide Capture and Storage Project,” Carbon Capture and Sequestration Technologies @ MIT. Accessed October 2, 2022. https://sequestration.mit.edu/tools/projects/boundary_dam.html.

6 “Boundary Dam Fact Sheet.”

7 “Boundary Dam 3 Carbon Capture and Storage (CCS) Facility,” International CCS Knowledge Centre. Accessed October 2, 2022. https://ccsknowledge.com/bd3-ccs-facility.

8 For reference, in 2019, coal-fired power generation in the U.S. produced approximately one metric tonne of CO2 per MW-hr of electricity, while natural gas-fired power generation in the U.S. produced approximately 0.4 metric tonnes of CO2 per MW-hr of electricity. See “Electric power sector CO2 emissions drop as generation mix shifts from coal to natural gas,” U.S. Energy Information Administration, June 9, 2021. Accessed November 15, 2022. https://www.eia.gov/todayinenergy/detail.php?id=48296.

9 “Boundary Dam Fact Sheet.”

10 “Boundary Dam Fact Sheet.”

11 Anchondo, Carlos, “CCS ‘red flag?’ World’s sole coal project hits snag,” E&E News Energy Wire, January 10, 2022. Accessed October 2, 2022. https://www.eenews.net/articles/ccs-red-flag-worlds-sole-coal-project-hits-snag/.

12 “Petra Nova: Carbon capture and the future of coal power,” NRG Energy. Accessed October 2, 2022. https://www.nrg.com/case-studies/petra-nova.html.

13 Patel, Sonal, “Capturing Carbon and Seizing Innovation: Petra Nova is POWER’s Plant of the Year,” POWER, August 1, 2017. Accessed October 2, 2022. https://www.powermag.com/capturing-carbon-and-seizing-innovation-petra-nova-is-powers-plant-of-the-year/.

14 Patel, Sonal, “Capturing Carbon and Seizing Innovation.”

15 Groom, Nichola, “Problems plagued U.S. CO2 capture project before shutdown: document,” Reuters, August 6, 2020. Accessed October 2, 2022. https://www.reuters.com/article/us-usa-energy-carbon-capture/problems-plagued-u-s-co2-capture-project-before-shutdown-document-idUSKCN2523K8.

16 “Petra Nova: Carbon Capture and the Future of Coal Power.”

17 “Diamond Vault FAQs,” Cleco. Accessed October 2, 2022. https://www.cleco.com/diamondvaultfaq.

18 Patel, Sonal, “DOE Backs Carbon Capture Development at Two Major Gas-Fired Power Plants,” POWER, September 1, 2022. Accessed October 2, 2022. https://www.powermag.com/doe-backs-carbon-capture-development-at-two-major-gas-fired-power-plants/.

19 Patel, “DOE Backs Carbon Capture Development.”

20 Patel, “DOE Backs Carbon Capture Development.”

21 Patel, “DOE Backs Carbon Capture Development.”

22 Patel, “DOE Backs Carbon Capture Development.”

23 Patel, Sonal, “Carbon Capture Begins at India’s Largest Coal Power Plant,” POWER, September 29, 2022. Accessed October 5, 2022. https://www.powermag.com/carbon-capture-begins-at-indias-largest-coal-power-plant/.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

Recommended Reads

Carbon Capture – A Capital-Intensive Technology with Large Growth Potential

This is the first post in a six-part series that discusses carbon capture, utilization, and sequestration (CCUS).

READ

Construction Claim Types for Contractors

U.S. federal and state courts recognize 19 basic construction claim entitlements for a contractor’s recovery of damages. This post is the first of a series discussing each of these 19 types.

READ

Definitions of Construction Claim Types for Contractors

The author summarizes the definitions of the 19 construction claim types that may apply to a contractor's and subcontractor's recovery of time and costs.

READ