December 11, 2023

Steps for Identifying the Critical Path

This blog post discusses steps for identifying the critical path on construction projects.

This is the last post in a five-part series that discusses critical path validity. The first post discusses the purpose of time management on construction projects, the second post concerns defining the critical path, and the third post addresses challenges to validating the critical path. The fourth post addresses schedule quality checks to improve the accurate identification of critical and near-critical paths.

After considering schedule deficiencies or errors, as suggested in the fourth post in this series, the following steps can aid in the identification and analysis of the critical and near-critical paths. These steps provide structure, organization, and consistency to the process and allow one to sequence information in a format that communicates clearly to project stakeholders. These steps are useful regardless of the schedule file size, although some steps may require modification, and additional steps may be added, depending on the data in the file. The steps stem from using the scheduling software Primavera P6 Professional (“P6”).

Step 1: Select and Copy the Appropriate Schedule File

Ensure that the schedule file being analyzed is the correct and most current version and save a copy of the original. Prepare a tracking table to log original versus copy filenames along with summary schedule data for each file (i.e., filename, number of activities, forecasted overall finish date, schedule calculation mode, budget resource totals, etc.).

Step 2: Create Critical and Near-Critical Codes

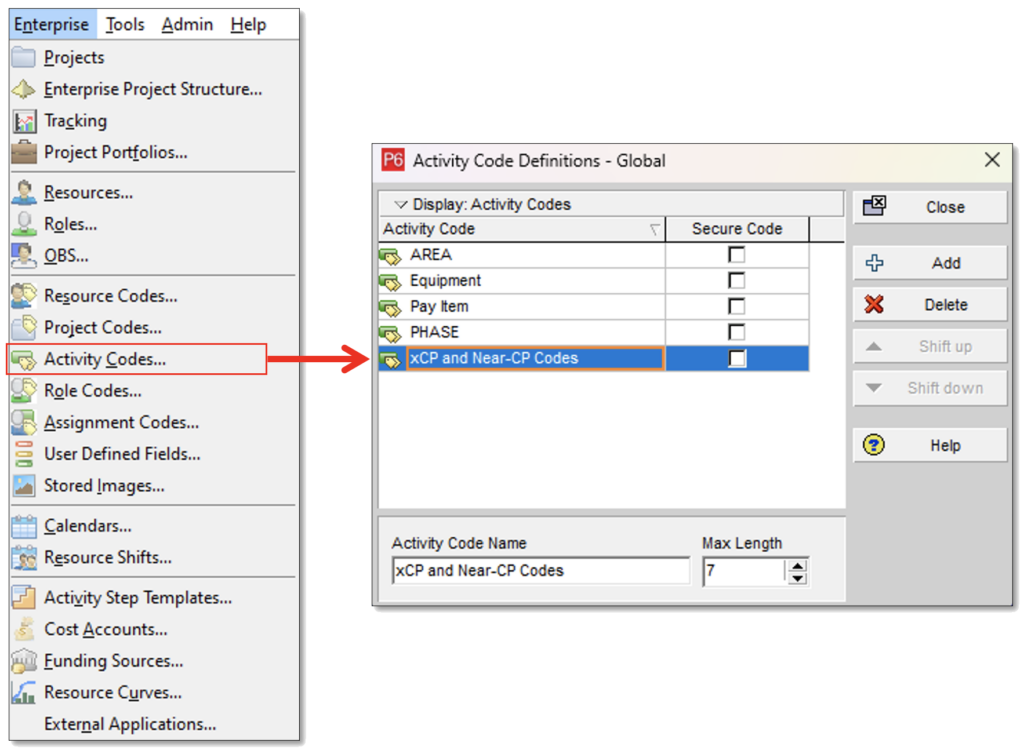

P6 allows users to create codes and assign them to schedule activities. The codes can be assigned and applied globally (i.e., across all projects contained within the P6 database), to defined Enterprise Project Structure (EPS) groups, or to individual projects only. Figure 1 shows the P6 menus used to create critical and near-critical path codes.

Figure 1

P6 Menu Items to Create Critical and Near-Critical Path Codes

In the example shown above, the critical and near-critical path codes are created for global use.

Step 3: Define Critical and Near-Critical Path Codes

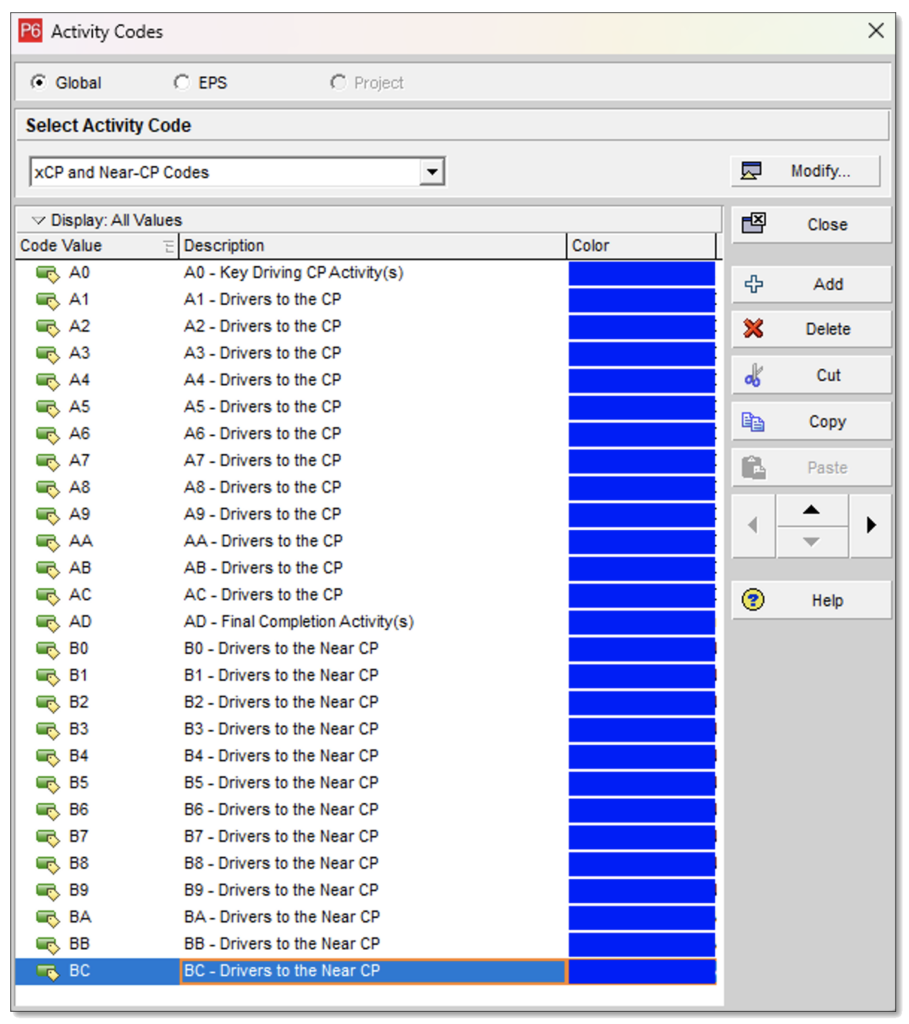

After creating the global category, define the critical and near-critical path codes for this category. These codes are used as groups that provide structure and flexibility when identifying and coding activities on these paths. Figure 2 shows sample critical and near-critical path codes to be applied to schedule activities.

Figure 2

Defined Critical and Near-Critical Path Code Menu

In the figure above, reference codes A0 through AD define the critical paths, and codes B0 through BC define near-critical path activities.

Step 4: Identify and Code the Latest Finish Activity

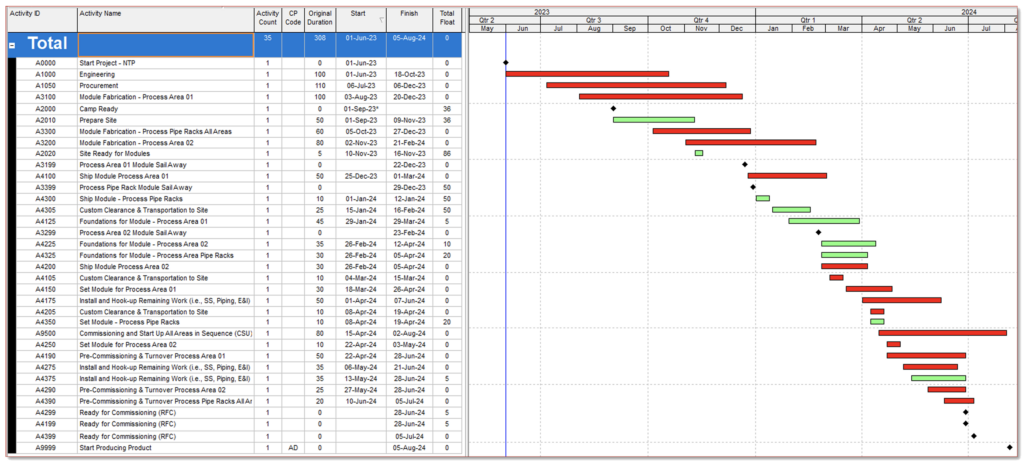

Identify and code the latest finishing work activity in the schedule file. To illustrate, Figure 3 is an activity listing of a simple process plant project with the schedule data sorted by early start.

Figure 3

Identify and Code the Latest Finishing Activity

In Figure 3, the latest finishing activity is identified as activity A9999 (Start Producing Product) and is assigned the critical path code AD.

Step 5: Identify and Code Driving Predecessor Activities

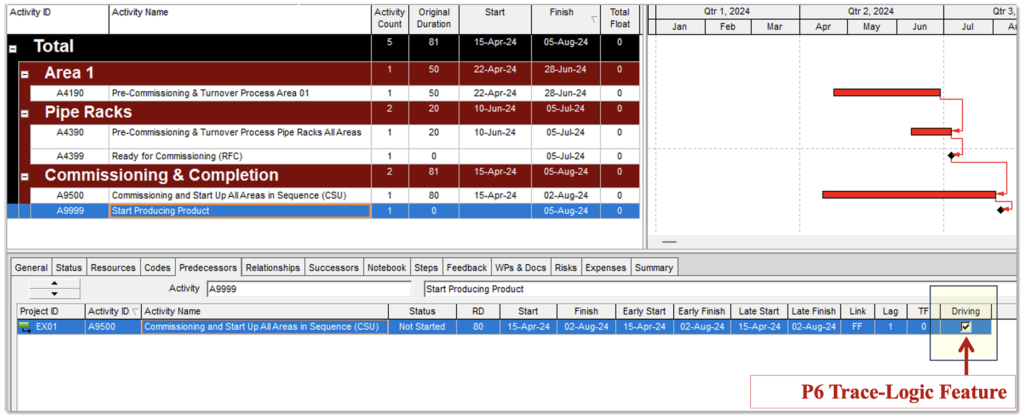

Use the “trace-logic” feature in P6 to identify the driving predecessor activity that controls the forecasted dates for activity A9999. Assign this driving predecessor a driving critical path code. Figure 4 illustrates this process.

Figure 4

Identification of Driving Predecessors from Activity A9999

In Figure 4, the “trace-logic” feature in P6 is designated by the yellow-highlighted “Driving” box with a check mark in the Predecessors tab below the bar chart information. Using this process, the driving predecessors for the path can be traced and coded all the way back to the data date.

Step 6: Organize and Summarize the Critical Path

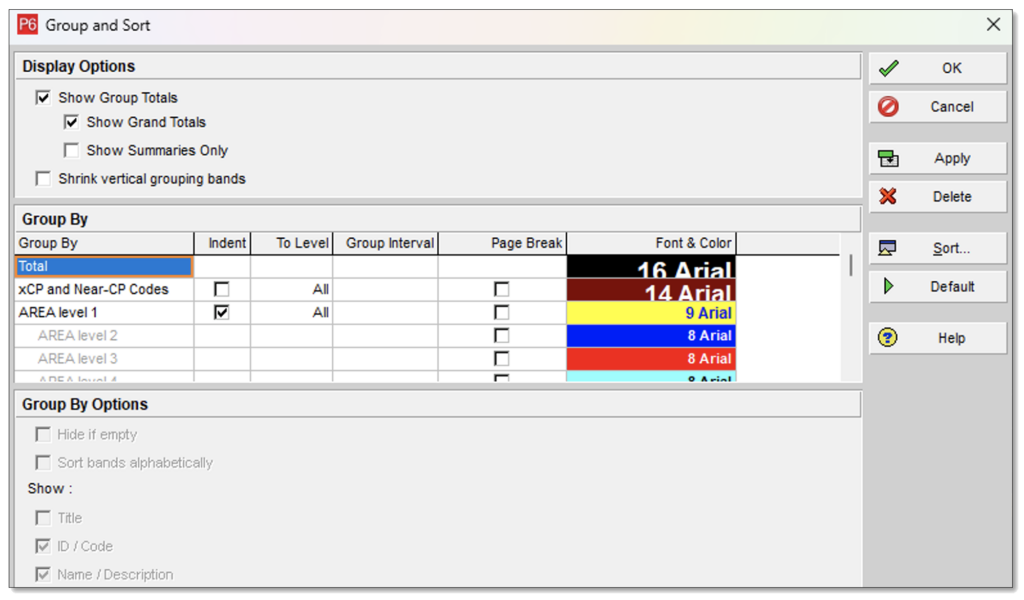

After assigning critical path codes to all driving predecessors back to the data date, the schedule data can then be organized and summarized by descending critical path codes for further examination of reasonableness. Figure 5 is an example of the P6 grouping and sorting menu options for this step.

Figure 5

P6 Critical Path Grouping and Summarization

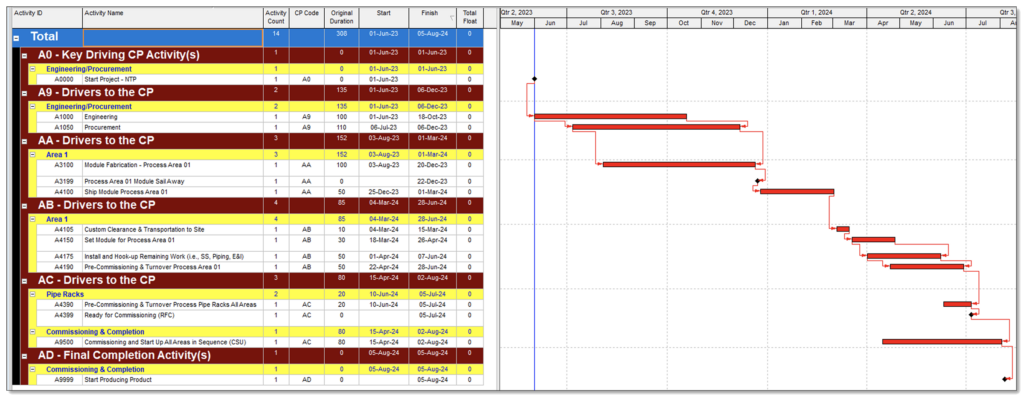

Based on the criteria in Figure 5, a summary of the critical path for the project can be generated. Figure 6 is the final generated critical path chart for the project.

Figure 6

Final Critical Path Summary

The same steps can be applied when determining near-critical paths. Based on the output from Figure 6, the user can then further examine the path for reasonableness. Areas to check and consider include but are not limited to the following:

- Reasonableness of constraints on the path, if any;

- Unusually long gaps or non-work periods between critical path activities;

- Questionable logic links on the path (i.e., use of start-to-finish links and negative lags); and

- Consistency with contemporaneous project records.

It is recommended that key project participants perform joint reviews of the final critical path summary information to ensure that all parties agree with the results. Based on these reviews, the critical path can be validated. Further, it is recommended to cross check the results with other documents such as the project charter, Front-End Engineering Design (FEED) documents, estimate information, and schedule basis memorandum information.

Conclusion

Identification and analysis of the critical path can be challenging, especially for large and complex EPC projects with tens of thousands of activities. Some standard graphical and tabular presentation features in the schedule software complicate the process. However, simple steps can be applied to code critical and near-critical activities to better identify, organize, and summarize these activities for further analysis and assessment.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

RECOMMENDED READS

Challenges and Considerations in Identifying and Analyzing the Critical Path

This first post in a series on identifying and analyzing the critical path discusses the purpose of time management on construction projects.

READ

The Critical Path Defined

This post explores various kinds of critical paths. It is the second post in a series on identifying and analyzing the critical path.

READ

Is the Critical Path Valid?

This post addresses challenges to determining the validity of the critical path. It is the third post in a series about critical path validity.

READ