July 5, 2023

Onshore Wind Farm Planning: Site Selection, Requirements, and More

This blog post is the second in a five-part series related to onshore wind project development. The series covers topics including onshore wind turbine and wind farm basics, planning and scheduling considerations for onshore wind farms, the permitting and approval process, and construction considerations for onshore wind farms. Offshore wind facilities will be discussed in a separate blog post series.

The planning and scheduling of a large wind farm is not unlike the planning and scheduling of other large and complex construction projects. However, due to the many tasks that must be completed for planning, permitting, approvals, and the long lead time of wind turbine components, diligent early planning and scheduling is a vital step in the successful completion of the project. A well-planned and detailed schedule may be a necessary step for the successful completion of the project and to avoid construction claims.

Unlike construction projects in which the land is owned, much of the land for a wind farm may be leased, creating a different set of challenges than other large construction projects. Due to permitting, public perception considerations, approvals, and the lead time of wind turbine components, planning and developing a commercial-size wind farm can take many years to complete. These time-consuming steps occur after the selection of the site for the wind farm.

Selection of the Wind Farm Site

During evaluation of a potential site for a wind farm, several key factors are considered. The first criteria is the wind resource itself. A site should be selected based on historical wind data and the associated electrical production potential. These considerations will help to maximize the wind turbine efficiency. Another consideration is the proximity and capacity of an electrical system (grid) and the potential to connect to that system. A potential wind farm site may not be feasible due to limitations on the electrical system in the area, and the cost to build infrastructure to a system farther away may be too expensive and may render the project impractical. Access to nearby transmission lines and the capacity of those lines may be as important as the wind resource.

Another consideration is the perception of wind energy in the area. Choosing a place where wind energy is not viewed positively may be problematic. If some of the development is on private land, land use agreements will be necessary, and public perception is critical in these situations. Sites with low population density are typically favorable because developers may face less public opposition.

Additionally, environmental impacts must be evaluated, and any impacts should be mitigated as much as possible. If a site will experience significant environmental impacts, developers may face obstacles during the permitting process at the local, state, and/or federal level. The selected site must also be compatible with existing land use zoning requirements.

A developer should also consider access to the site. Due to the size of wind turbine components, road and rail considerations are a key factor. Additionally, future road and rail infrastructure should be considered. The logistic planning considerations of a wind farm may occur years prior to the components being transported to the site. If a certain highway is unavailable during the procurement of components, selection of another route for delivery may render the project financially unviable. If there are highway overpasses on the transportation route, the clearance must be evaluated to ensure large wind turbine tower components will fit within the clearance. For these reasons, coordination with state departments of transportation may be necessary to determine if the planned delivery routes will be available when the components are shipped.

After preliminary selection of a wind turbine site, a feasibility study is typically performed. Much of the work involved in this study can be used in detailed planning and design. This feasibility study is a thorough evaluation of the project to determine if the development is a reasonable investment for all project stakeholders and investors. One key aspect of the feasibility study is an interconnection analysis to determine if the electrical grid has capacity to transmit additional power and the costs to do so. The interconnection study will be addressed in a future blog post.

Planning and Scheduling Considerations for the Wind Farm

After the selection of the site and completion of a feasibility study, there are many time-consuming tasks that must be completed in the planning, design, procurement, and construction processes. At this early stage in any large construction project, the preparation of a detailed schedule is recommended.

AACE International (AACE) is a respected, non-profit, professional organization of cost estimators, cost engineers, schedulers, project managers, project control specialists, and forensic schedule analysts. Over the years, the organization has published a series of recommended practices that serve as guidelines for its members, as well as for the construction industry. AACE’s recommended practices are created and publicly commented on by industry practitioners before being published.

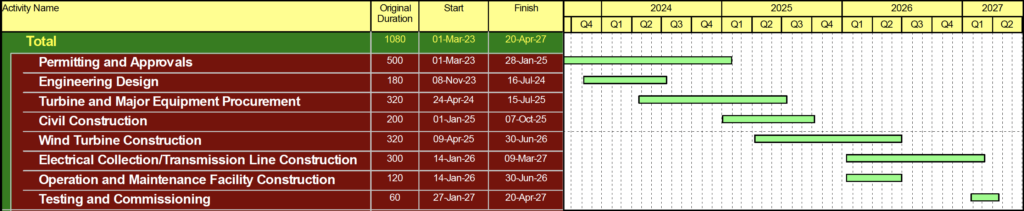

AACE defines schedule levels from Level 1 through Level 4, with Level 1 being a high-level management schedule, and a Level 4 schedule being the most detailed.1 An example of a Level 1 schedule for a hypothetical wind farm is shown in Figure 1 below.

Figure 1: Level 1 Wind Farm Schedule2

As shown in the above figure, a Level 1 schedule is a high-level schedule that all project stakeholders can use to monitor all phases of the project.

AACE’s recommended practice indicates that in an EPC project, the schedule detail may be developed as the project progresses. In the case of a wind farm project, during the engineering and permitting phase, the engineering and permitting portion of the schedule may be fully developed, while the procurement and construction portion of the schedule is at a summary level. As engineering completes and procurement begins, it is expected that the level of detail in the procurement section of the schedule is further developed. Similarly, as the details for construction come together, the construction activities in the schedule should be developed.

This type of schedule is best managed in an electronic Critical Path Method (CPM) schedule in which interrelated tasks can be linked with logic and the use of total float can be used to determine work priorities and the critical path to project completion.

Because most wind farms are in remote locations, the industry typically utilizes non-local labor for construction. Also, cranes used for wind turbine erection are very specialized, and availability is often limited. The cranes may be shipped from a location far from the project site. When delay occurs on a wind farm project, costs may quickly escalate because cranes and crews may be required to shift to another project at a specified date that was likely based on the original construction schedule. The delay may result in large costs for accelerating work to utilize the resources before they shift to another project.

1 AACE International Recommended Practice No. 37R-06, “Schedule Levels of Detail – As Applied in Engineering, Procurement and Construction,” dated 20 March 2010.

2 The durations, dates, and overlap of the activities in Figure 1 are based on a rough estimate of durations established during the author’s research. The intent of the graphic is only to show how a Level 1 schedule for a wind farm may be organized and is not intended to represent historical durations or logic.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

RECOMMENDED READS

Onshore Wind Turbine Basics: Parts, Power Generation, and More

This post on wind power basics and the components of wind turbines and wind farms is the first in a series about onshore wind energy.

READ

Carbon Capture – A Capital-Intensive Technology with Large Growth Potential

This is the first post in a six-part series that discusses carbon capture, utilization, and sequestration (CCUS).

READ

Construction Claim Types for Contractors

U.S. federal and state courts recognize 19 basic construction claim entitlements for a contractor’s recovery of damages. This post is the first of a series discussing each of these 19 types.

READ